BIM for Prefabrication Services

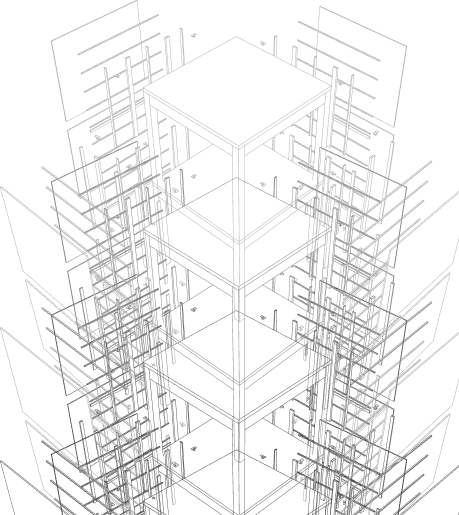

In the evolving construction landscape, BIM for Prefabrication represents a transformative approach that integrates advanced digital modeling with modern manufacturing methods to create a more efficient building delivery process. Our specialized services leverage Building Information Modeling to support off-site production of building components, systems, and assemblies—shifting substantial work from unpredictable field environments to controlled manufacturing settings. We develop precise digital models that drive fabrication systems, coordinate production logistics, and ensure seamless on-site assembly, enabling projects to realize the full benefits of prefabrication including accelerated schedules, improved quality, enhanced safety, and optimized resource utilization.

Prefabrication Services

- Manufacturing-ready BIM models with fabrication-level detail and specifications

- Detailed component design optimized for off-site production processes

- Multi-trade prefabrication coordination and assembly sequencing

- Digital fabrication integration with manufacturing systems and equipment

- Comprehensive installation planning for prefabricated component assembly

Comprehensive Prefabrication Solutions

Our BIM for Prefabrication services deliver manufacturing-ready digital assets that drive successful off-site production across diverse building systems. We create highly detailed component models with precision geometry, complete material specifications, connection details, and assembly information required for modern manufacturing processes. These specialized models serve as the definitive digital representation of prefabricated elements, maintaining consistent information from design through fabrication and installation while ensuring prefabricated components integrate seamlessly with the overall building project.

Beyond basic geometric modeling, our prefabrication approach addresses the complex manufacturing and logistical requirements that define successful off-site construction. We implement component identification systems that support production tracking, develop phasing strategies that optimize manufacturing resources, and create assembly simulations that validate process efficiency. Our comprehensive documentation includes fabrication drawings, manufacturing instructions, quality control protocols, shipping requirements, and installation guidelines—providing complete information continuity from factory to field. This holistic approach transforms traditional construction practices into modern manufacturing processes that improve predictability, quality, and efficiency throughout project delivery.

Strategic Benefits of BIM-Enabled Prefabrication

Implementing BIM-enabled prefabrication delivers transformative advantages that fundamentally improve project outcomes. Schedule acceleration represents one of the most significant benefits, with prefabrication reducing overall project timelines by 20-50% through parallel production activities, weather independence, and rapid on-site assembly. This approach dramatically improves construction productivity and enables earlier building occupancy and revenue generation. Quality improvements result from controlled manufacturing environments where standardized processes, proper tool access, and comprehensive inspection protocols produce consistently superior results compared to traditional field construction.

Beyond time and quality enhancements, prefabrication delivers substantial operational benefits throughout the project lifecycle. Cost efficiency improves through optimized material usage, reduced labor hours, minimized rework, and decreased site overhead costs. Safety performance increases significantly by relocating high-risk activities from hazardous site conditions to controlled manufacturing settings with proper ergonomics, appropriate equipment, and consistent processes. For occupied renovations and sensitive locations, prefabrication minimizes on-site disruption by reducing noise, dust, and construction traffic while shortening field installation periods. These combined benefits create compelling value for projects where schedule, quality, and operational performance drive success metrics.

Industry Applications of BIM Prefabrication

Healthcare Facilities

Specialized prefabrication for healthcare environments including headwalls, bathroom pods, MEP racks, equipment rooms, and clinical modules. Our healthcare prefabrication addresses the unique requirements of these facilities including infection control, medical gas certification, equipment integration, and operational continuity. The approach enables superior quality control for critical systems, reduces on-site contamination risks, and shortens construction duration in sensitive healing environments.

Multi-Unit Residential

Comprehensive prefabrication for multi-family housing, student accommodation, and hospitality projects with repeating unit types. Our residential prefabrication includes bathroom pods, kitchen modules, utility risers, facade panels, and volumetric room modules that leverage repetition for manufacturing efficiency. This approach accelerates delivery schedules, improves unit consistency, enhances acoustic performance, and enables quality levels typically associated with product manufacturing rather than traditional construction.

Data Centers & Mission Critical

Advanced prefabrication for data centers and mission-critical facilities including equipment skids, power distribution modules, cooling assemblies, and containment systems. Our critical facility prefabrication addresses the specialized requirements of these environments including testing certification, performance validation, and operational commissioning. The approach enables accelerated deployment, factory-verified system performance, and consistent implementation of critical infrastructure components.

Commercial & Mixed-Use Development

Strategic prefabrication for commercial projects and mixed-use developments including facade systems, structural components, service distribution, and interior assemblies. Our commercial prefabrication optimizes high-value and repetitive elements to improve schedule performance on these schedule-sensitive investments. The approach enables earlier tenant occupancy, reduced financing periods, superior quality for public-facing elements, and enhanced coordination between diverse building systems.

Why Choose Us

Advanced Prefabrication Solutions That Transform Construction Delivery

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

BIM for Prefabrication is the specialized application of Building Information Modeling to support off-site manufacturing of building components and assemblies. This approach creates precise digital representations of prefabricated elements with manufacturing-level detail, material specifications, connection interfaces, and assembly sequences. BIM for Prefabrication transforms construction by shifting substantial work from unpredictable field environments to controlled manufacturing settings, resulting in 20-50% faster project delivery, 10-25% lower project costs, improved quality through standardization, enhanced worker safety, reduced site disruption, and decreased material waste. This methodology fundamentally changes how buildings are delivered by integrating digital precision with manufacturing efficiency while maintaining seamless coordination with the overall building project.

BIM supports prefabrication across virtually all building systems and components. For structural systems, we model prefabricated steel assemblies, precast concrete elements, engineered wood components, and modular foundation systems. Building envelope prefabrication includes unitized curtain wall panels, preassembled facade components, modular wall assemblies, and integrated exterior systems with windows and finishes. MEP systems are particularly suited for prefabrication, including multi-trade overhead rack assemblies, bathroom pods, utility risers, equipment skids, and preassembled distribution networks. Additionally, BIM enables prefabrication of architectural elements including millwork assemblies, finish systems, stair modules, and complete volumetric modules for residential, healthcare, and hospitality applications. This comprehensive approach can extend to site elements, equipment integrations, and specialty systems where off-site assembly improves quality and efficiency.

BIM models for prefabrication require exceptional detail beyond standard construction modeling. Typical prefabrication models achieve LOD 400-450 (Level of Development) with precise geometric representation, complete material specifications, connection details, and assembly information. These models include exact dimensions with appropriate tolerances, material properties including performance characteristics, and manufacturing-specific attributes such as surface treatments and finishing requirements. Connection interfaces are modeled with fastener details, integration provisions, and assembly references. Prefabrication models incorporate transportation provisions, lifting points, temporary bracing requirements, and installation guides. Additionally, these models include component identification systems, manufacturing categorization, and tracking parameters that support production management and quality control throughout the prefabrication process.

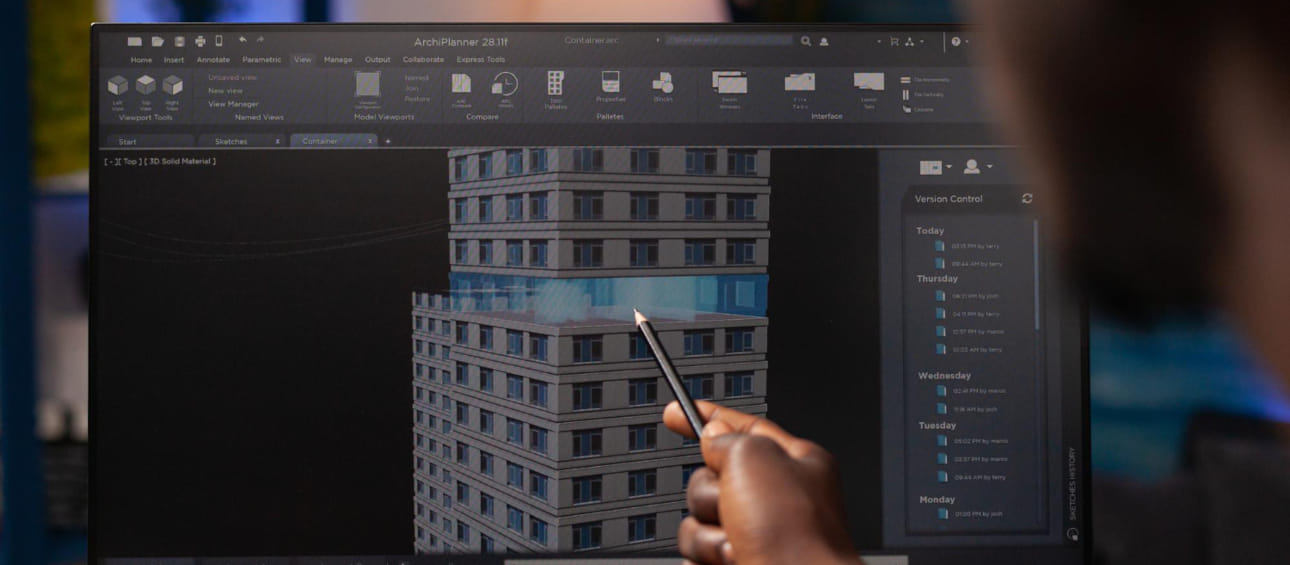

We employ specialized technology ecosystems tailored to specific prefabrication applications. Our primary platforms include Revit with advanced manufacturing extensions, Tekla Structures for steel and concrete prefabrication, Inventor and SolidWorks for complex component modeling, and Navisworks for assembly verification. These are augmented by fabrication-specific tools including Autodesk Fabrication CADmep, SysQue, and Trimble for MEP prefabrication. For manufacturing integration, we implement digital exchange protocols including STEP, IFC, and direct API connections that enable seamless transfer to production systems such as CAM software, CNC equipment, robotic assembly, and quality control platforms. Throughout the process, our cloud collaboration tools maintain synchronization between design development, manufacturing progress, and site installation to ensure successful integration of prefabricated elements.

We implement comprehensive integration strategies to ensure prefabricated components fit perfectly within the overall building context. The foundation of our approach is rigorous multi-discipline coordination, clash detection, and spatial validation before prefabrication begins, eliminating potential conflicts. We establish clear dimensional control with primary reference points, tolerance management protocols, and field verification procedures that maintain alignment between prefabricated and site-built elements. Interface control documentation defines the exact relationship between prefabricated elements and adjacent construction with critical connection details and assembly sequences. For complex projects, we create digital assembly simulations that verify component relationships before manufacturing. Throughout fabrication and installation, our quality control procedures compare as-built conditions to the coordinated model, confirming proper integration while providing adjustment strategies for field variations.

Our prefabrication process follows a structured methodology beginning with prefabrication opportunity assessment that identifies optimal components for off-site production based on repetition, complexity, and schedule impact. Conceptual prefabrication planning establishes module definitions, interface strategies, and logistics considerations that shape the approach. Detailed prefabrication modeling then develops manufacturing-ready BIM content with component-specific detail, material specifications, and assembly information. This model drives comprehensive documentation including fabrication drawings, assembly instructions, QA/QC protocols, and installation guides tailored to manufacturing requirements. Throughout production, the model supports digital fabrication through direct machine connections, tracking systems, and verification procedures. For installation, we provide specialized documentation including lifting plans, sequencing guides, and connection procedures that ensure successful field assembly. This integrated process maintains digital continuity from concept through installation while supporting quality manufacturing.

BIM for Prefabrication provides powerful tools for schedule optimization and logistics management throughout the project lifecycle. The model-based approach enables detailed production scheduling with accurate time estimation for each prefabricated component, supporting manufacturing resource allocation and progress tracking. By integrating this production schedule with the overall construction timeline, we develop optimized delivery sequences that align manufacturing completion with installation readiness, enabling just-in-time delivery that reduces on-site storage requirements. The model supports detailed installation planning with activity sequencing, crane positioning, access requirements, and temporary support needs fully defined before field operations begin. Throughout construction, the prefabrication model serves as a central coordination platform where design teams, manufacturers, logistics providers, and field crews maintain schedule alignment, track progress, and manage the complex dance of off-site and on-site activities that defines successful prefabrication projects.

BIM-enabled prefabrication delivers substantial and quantifiable benefits that transform project outcomes. Schedule improvements typically range from 20-50% reduction in overall delivery time through parallel manufacturing and site activities, weather independence, and efficient installation. Cost benefits include 10-25% savings from reduced labor hours, minimized rework, decreased site overhead, and optimized material usage. Quality improvements result from controlled manufacturing environments, standardized processes, comprehensive testing before delivery, and reduced field improvisations. Safety metrics show significant incident reduction by moving work from hazardous site conditions to controlled settings with proper ergonomics. Additional benefits include sustainability improvements through reduced material waste, decreased site disruption in sensitive locations, enhanced labor productivity, and improved facility maintenance through standardized, well-documented components. For optimal projects, ROI analysis typically shows 3-10x return on the additional investment in prefabrication modeling and planning.

Wide Range of SERVICES

Other BIM Coordination

Discover our comprehensive coordination services that ensure seamless integration between all building systems, minimizing conflicts and optimizing construction efficiency.

Coordinate multi-discipline models to identify and resolve conflicts before construction, improving project efficiency and reducing costly site rework.

Identify and resolve spatial conflicts between building systems using advanced BIM clash detection tools and methodologies.

Develop detailed shop drawings from BIM models for various building components, facilitating precise fabrication and installation.