Curtain Wall Detailing Services

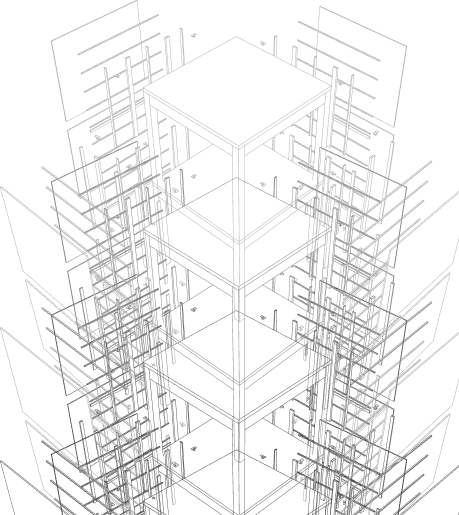

In contemporary building envelope design and construction, Curtain Wall Detailing provides the critical technical foundation for successful glazed facade implementation. Our specialized documentation services develop comprehensive technical drawings for curtain wall systems including detailed mullion profiles, transom designs, glazing methods, connection details, and weatherproofing provisions. We create precise documentation packages that define exactly how curtain wall components are manufactured, assembled, and installed to create high-performance building envelopes that deliver both architectural expression and environmental separation.

Curtain Wall Services

- Comprehensive mullion and transom detailing with precise profile dimensions

- Detailed connection designs for all system conditions and interfaces

- Complete weatherproofing details for gaskets, sealants, and drainage systems

- Structural attachment documentation with anchor and support specifications

Comprehensive Curtain Wall Documentation

Our Curtain Wall Detailing services provide thorough technical documentation for all glazed facade system types including stick-built assemblies, unitized panels, structural silicone glazing, and point-supported systems. We develop detailed component drawings that precisely define each element of the curtain wall assembly from primary extrusions and reinforcing members to gaskets, pressure plates, and cover caps. These comprehensive details establish exact dimensions, material specifications, finish requirements, and fabrication information for all system elements, creating complete documentation packages that support both manufacturing and installation processes.

Beyond individual component definition, our curtain wall documentation addresses the complex relationships between elements that determine system performance and appearance. We develop connection details for all conditions including mullion-to-transom joints, stack connections, expansion provisions, corner conditions, and perimeter transitions. These critical interface details define exact assembly methods, fastener requirements, sealant applications, and tolerance provisions that ensure proper system integration. Throughout our documentation, we maintain exceptional attention to weatherproofing details, structural considerations, and performance requirements that create a complete technical foundation for successful curtain wall implementation.

Strategic Benefits of Detailed Curtain Wall Documentation

Comprehensive Curtain Wall Detailing delivers substantial benefits throughout the building envelope implementation process. During design development, detailed documentation enables accurate performance evaluation, aesthetic refinement, and technical validation of facade concepts before construction commitments are made. These detailed drawings support meaningful coordination with other building systems, preventing conflicts and alignment issues before field installation begins. For project management, thorough curtain wall detailing supports precise cost estimation, accurate material procurement, and reliable scheduling of this critical project component.

During manufacturing and construction, detailed curtain wall documentation prevents costly errors and inefficiencies by providing complete information to fabricators and installers. Manufacturing operations benefit from precise component definitions that support efficient production planning and quality control procedures. Field installation teams receive clear assembly instructions, anchor layouts, and tolerance information that streamline on-site operations and prevent improvisational problem-solving. Throughout the curtain wall lifecycle, comprehensive documentation establishes clear performance expectations, defines verification methods, and provides reference information for future maintenance or modifications to these complex building systems that form the primary environmental separator and visual expression of the building.

Industry Applications of Curtain Wall Detailing

Commercial Office Developments

Specialized curtain wall detailing for commercial office buildings including high-rise towers, mid-rise developments, and corporate headquarters with performance-driven envelope requirements. Our commercial curtain wall documentation addresses the specific needs of these projects including efficient system deployment, lease-line optimization, and pragmatic detailing that balances aesthetic goals with construction economy to deliver high-value building assets.

Signature Architectural Projects

Comprehensive curtain wall detailing for signature buildings, cultural institutions, and public projects with distinctive facade expressions. Our architectural curtain wall documentation addresses the unique requirements of these projects including custom extrusion development, specialized glazing systems, and innovative connection designs that realize ambitious design concepts while ensuring technical performance and constructability.

Performance-Critical Facilities

Detailed curtain wall documentation for facilities with exceptional performance requirements including laboratory buildings, healthcare facilities, and mission-critical installations. Our performance-focused detailing addresses stringent thermal performance, air/water infiltration control, blast resistance, hurricane impact protection, and acoustic isolation with specialized system configurations and enhanced details that meet demanding technical requirements.

Renovation & Retrofit Projects

Specialized curtain wall detailing for building renovations, facade replacements, and envelope upgrades with existing condition constraints. Our retrofit curtain wall documentation addresses the unique challenges of these projects including field verification integration, attachment to existing structures, and phased implementation requirements that enable successful facade renewal while accommodating the realities of existing buildings.

Why Choose Us

Precise Curtain Wall Documentation That Ensures Envelope Performance

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

Curtain Wall Detailing is the specialized process of developing comprehensive technical documentation for glazed facade systems including mullion profiles, transoms, glazing methods, connection designs, and weatherproofing details. This documentation defines precisely how curtain wall components are fabricated, assembled, and installed to create a complete building envelope system. Curtain wall detailing is critical because these systems form the primary environmental separator between interior and exterior conditions while supporting no structural loads beyond their own weight. Proper detailing ensures weathertightness, thermal performance, structural integrity, and longevity while achieving the desired architectural aesthetic. The non-load-bearing nature of curtain walls combined with their complex performance requirements demands exceptionally precise technical documentation to ensure successful implementation.

Our Curtain Wall Detailing services address the complete spectrum of glazed facade systems used in contemporary architecture. We provide comprehensive documentation for stick-built systems where individual mullions, transoms, and glazing components are assembled on-site from extruded profiles. For unitized curtain walls, we detail factory-assembled panels with complete component definition and connection interfaces that enable efficient installation of pre-assembled modules. Our services extend to structural silicone glazing (SSG) with four-sided, two-sided, and stepped configurations that create seamless glass appearances. We also document point-supported systems including spider fittings, tension rod structures, and cable-supported walls that minimize visible structure. Additionally, we provide detailing for specialty applications including sloped glazing, skylights, canopies, vestibules, and custom facade elements that integrate with standard curtain wall systems to create complete building envelope solutions.

Our Curtain Wall Detailing provides exceptional documentation depth tailored to specific project requirements and system complexity. Standard documentation includes comprehensive system overview drawings showing configuration, primary dimensions, and key relationships between components. Detailed mullion and transom drawings define exact extrusion profiles, internal reinforcing, thermal breaks, and accessory components with precise dimensions and material specifications. Connection details document all interfaces including stack joints, expansion provisions, and corner conditions with appropriate fastener specifications and assembly instructions. Glazing details specify glass types, gasket systems, pressure plates, and cap profiles with complete weatherproofing provisions. Anchorage documentation defines the interface between curtain wall and building structure including embed details, adjustment mechanisms, and load transfer provisions. For manufacturing and installation support, we provide component schedules, hardware specifications, assembly sequences, and quality control references. All documentation is developed with appropriate scales, annotation standards, and dimensioning systems that ensure clarity and precision throughout the fabrication and installation process.

Performance integration is fundamental to our Curtain Wall Detailing methodology. We incorporate comprehensive performance considerations throughout the documentation process, beginning with clear identification of system requirements including structural loading criteria, air/water infiltration limits, thermal transmission targets, acoustic attenuation needs, and fire resistance provisions. The resulting details explicitly address weatherproofing through precise documentation of gasket systems, sealant applications, pressure equalization chambers, and drainage paths that prevent water intrusion. Thermal performance is addressed through detailed thermal break specifications, placement of insulating elements, and minimization of conductive paths. Structural integrity is ensured through explicit documentation of load paths, connection designs, and reinforcement provisions that accommodate specified wind loads, seismic requirements, and building movements. Additional performance aspects including acoustic isolation, condensation resistance, and solar control are addressed through appropriate material specifications and assembly details that create a comprehensive high-performance envelope system. Throughout the documentation, we incorporate industry standards, testing requirements, and performance verification methods that establish clear expectations for the installed system.

Comprehensive interface coordination is a cornerstone of our Curtain Wall Detailing approach. We implement systematic coordination processes that define precise relationships between curtain wall components and all adjacent building elements. For structural integration, we develop detailed anchor documentation showing exact connection locations, load transfer mechanisms, and adjustment provisions with appropriate tolerance accommodations that ensure proper fit while accommodating building movements. Adjacent system coordination includes explicit transition details between curtain wall and other envelope elements including roofing, waterproofing, opaque wall systems, and entry features with continuous weatherproofing integration to maintain envelope integrity. Interior interface details define the relationship between curtain wall and interior finishes including perimeter conditions, sill details, and ceiling transitions that ensure proper fit and finish. MEP coordination addresses penetrations, equipment attachments, and service integration requirements including electrical pathways, lighting connections, and mechanical interfaces. Throughout the coordination process, we maintain dimensional control references, tolerance management strategies, and construction sequence considerations that ensure successful integration of the curtain wall with all building systems.

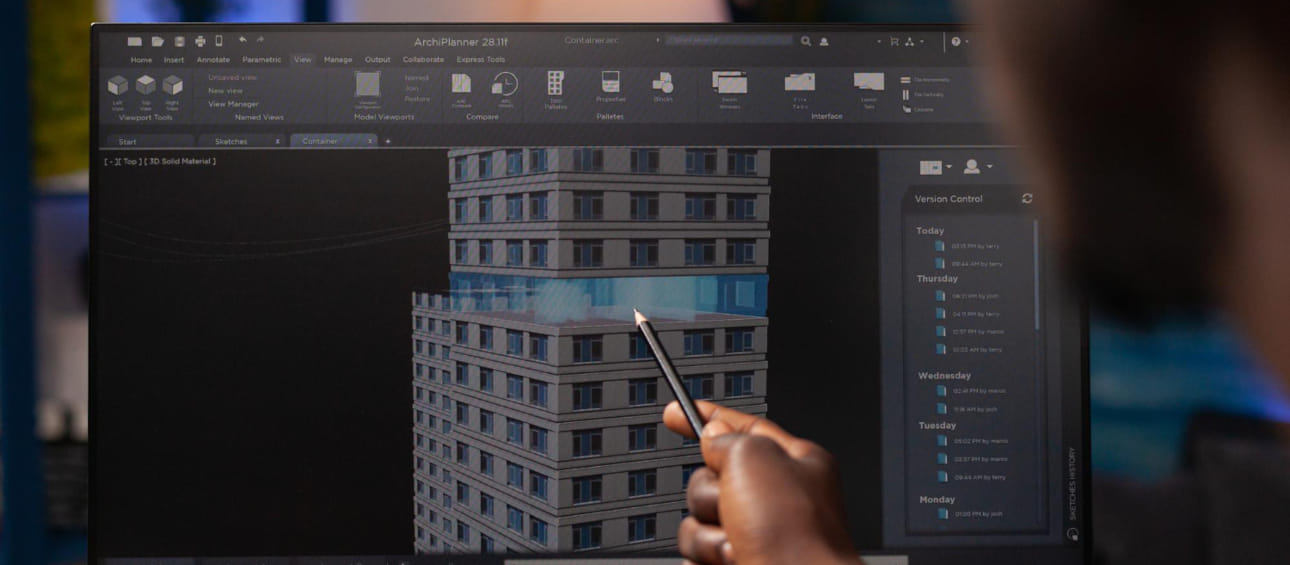

Our Curtain Wall Detailing follows a structured development methodology that ensures comprehensive, accurate documentation. The process begins with detailed analysis of project requirements including architectural design intent, performance specifications, and site conditions to establish system parameters. For standard systems, we confirm manufacturer capabilities, catalog components, and system limitations that inform the documentation approach. Preliminary development focuses on system configuration, primary dimensions, and critical interfaces with schematic details that establish the overall approach. Following stakeholder approval, we proceed with comprehensive detail development addressing all components, connections, and performance elements with progressive refinement at appropriate scales. Throughout development, we implement rigorous quality assurance including dimensional verification, standards compliance, and constructability review. Technical coordination with other disciplines ensures proper integration with structural, architectural, and MEP systems. The completed documentation undergoes comprehensive checking procedures before submission, with revision management tracking changes through the review process until final acceptance. This systematic approach ensures complete, coordinated details that support successful curtain wall implementation.

Complex geometries and custom curtain wall elements require specialized detailing approaches that we have refined through extensive experience. For non-orthogonal conditions including curved facades, angled surfaces, and compound geometries, we employ sophisticated documentation techniques that precisely define three-dimensional relationships through appropriate projections, section development, and geometric controls. Complex corner conditions are documented with detailed component definition showing exact mitering requirements, internal reinforcing, and specialized connection elements that maintain system integrity at geometric transitions. For sloped glazing and overhead applications, we develop specialized details addressing additional performance requirements including condensation management, drainage provisions, and enhanced structural support. Custom facade elements receive comprehensive component-specific documentation including specialized extrusion profiles, non-standard connections, and unique assembly methods appropriate to the design intent and manufacturing capabilities. Throughout complex detailing, we emphasize constructability through rational geometric development, manageable component configuration, and practical assembly sequences that enable successful fabrication and installation while preserving architectural intent.

Our Curtain Wall Detailing services provide comprehensive deliverables tailored to project requirements and fabricator workflows. Standard documentation packages include detailed drawing sets with system elevations, grid layouts, typical details, isometric assemblies, component profiles, connection details, and installation instructions organized according to industry conventions. These are supplemented by component schedules, hardware specifications, glass schedules, and finish definitions that specify all required materials and parts. Technical submittals include product data, performance calculations, engineering verifications, and testing certifications that support system approval. Deliverable formats include both hard copy printing at appropriate scales and digital files in multiple formats including native CAD (typically DWG), PDF sets at production-ready resolution, and specialized formats for manufacturing systems where required. For fabrication support, we can provide CNC-ready data, 3D component models, and production information compatible with automated manufacturing equipment. All deliverables undergo comprehensive quality review before release, with detailed checking documentation that verifies completeness and accuracy.

Wide Range of SERVICES

Other Façade Modeling

Browse our specialized facade modeling services that provide detailed design, documentation, and fabrication support for complex building envelope systems.

Create detailed BIM models of building facades and envelope systems, supporting design development, analysis, and construction documentation.

Develop detailed fabrication and installation drawings for facade systems, curtain walls, storefront systems, and other envelope components.