Facade Shop Drawings and Detailing Services

In today's sophisticated facade construction, detailed Shop Drawings and comprehensive component detailing are essential for successful fabrication and installation of building envelope systems. Our specialized documentation services translate architectural design intent into precise manufacturing information for facade components including curtain walls, window systems, panel assemblies, and custom architectural features. We develop detailed fabrication drawings with exact dimensions, material specifications, connection details, and assembly instructions that enable accurate production, quality control, and efficient installation of these critical building systems.

Facade Documentation

- Comprehensive fabrication documentation for curtain wall and glazing systems

- Detailed panel system shop drawings with material and connection specifications

- Custom facade element detailing with precise manufacturing information

Comprehensive Facade Documentation Solutions

Our Facade Shop Drawing services deliver manufacturing-ready documentation that bridges the gap between architectural design and fabrication requirements. We develop detailed component drawings that translate design concepts into precisely defined facade elements with exact dimensions, material specifications, finishing requirements, and assembly information required for accurate production. Unlike design development drawings that express general intent, our shop drawings provide the complete technical information needed to fabricate, assemble, and install each facade component according to both visual design requirements and performance specifications.

We provide comprehensive documentation for all facade system types from standardized curtain wall and window assemblies to custom architectural features and complex geometric enclosures. Our drawing packages address both system-wide parameters and component-specific details with appropriate documentation hierarchy that organizes information effectively for manufacturing and installation. Throughout the documentation process, we incorporate industry standards, manufacturer guidelines, and performance requirements that ensure facade components meet functional requirements while achieving the intended architectural expression. This systematic approach delivers complete fabrication documentation that supports successful implementation of building envelope systems from factory production through field installation.

Strategic Benefits of Detailed Facade Documentation

Comprehensive Facade Shop Drawings deliver significant advantages throughout the construction process by providing precise information that prevents errors, reduces uncertainty, and improves efficiency. During pre-construction, these detailed documents enable accurate cost estimation, realistic scheduling, and proper resource allocation for facade fabrication and installation. The detailed specifications and drawings allow fabricators to procure exact materials, plan production processes, and allocate manufacturing resources effectively, resulting in more competitive pricing and reliable delivery timelines for these critical building components.

During manufacturing and construction, detailed shop drawings prevent costly errors and delays by providing complete information before production begins. Fabrication issues can be identified and resolved on paper rather than discovered during manufacturing or field installation where corrections are exponentially more expensive. For installation, comprehensive documentation streamlines field operations by providing clear directions, reducing on-site decision making, and minimizing requests for information (RFIs) that can delay progress. Throughout the entire process, detailed facade documentation supports quality control measures by establishing clear standards, verification methods, and acceptance criteria that ensure the completed facade system meets both visual design requirements and performance specifications.

Industry Applications of Facade Shop Drawings

High-Performance Commercial Facades

Specialized shop drawing services for commercial office buildings, corporate headquarters, and multi-tenant developments with sophisticated envelope requirements. Our commercial facade documentation addresses the particular needs of these projects including repetitive element optimization, performance certification, and efficient system deployment. These detailed drawings support cost-effective fabrication, efficient installation, and long-term performance for these investment-grade building assets.

Custom Architectural Facades

Comprehensive shop drawing development for signature architectural facades, cultural institutions, and public buildings with unique envelope expressions. Our custom facade documentation addresses the specialized requirements of these projects including non-standard geometries, custom component development, and innovative material applications. These detailed drawings translate design concepts into manufacturable components while preserving architectural intent and ensuring technical performance.

Prefabricated Facade Systems

Detailed documentation for unitized curtain walls, prefabricated panel systems, and modular facade elements designed for off-site manufacturing. Our prefabrication documentation addresses the unique requirements of these systems including factory assembly processes, transportation considerations, and field connection details. These specialized drawings enable efficient mass production while ensuring successful field assembly and weathertight integration.

Retrofit & Overcladding Projects

Specialized shop drawing development for facade renovations, building recladding, and envelope retrofits with existing condition constraints. Our retrofit documentation addresses the particular challenges of these projects including field verification integration, anchor attachment to existing structures, and phased implementation requirements. These detailed drawings ensure successful facade renewal while accommodating the realities of existing building conditions.

Why Choose Us

Precision Facade Documentation That Ensures Successful Implementation

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

Facade Shop Drawings are detailed manufacturing and installation documentation that translate architectural design intent into fabrication-ready instructions for building envelope components. Unlike design drawings that express conceptual intent and general configurations, shop drawings provide exact dimensions, material specifications, manufacturing details, and assembly instructions required for production. They include precise extrusion profiles, connection details, hardware specifications, gasket systems, sealant applications, and installation sequences with tolerances appropriate to manufacturing processes. Where design drawings show what the facade should look like, shop drawings explain exactly how to fabricate, assemble, and install each component to achieve the design intent while meeting performance requirements and industry standards.

Our Facade Shop Drawing services accommodate the complete spectrum of building envelope systems. For glazed systems, we document curtain walls (stick-built, unitized, point-supported), window walls, storefronts, skylights, and custom glazing assemblies. Panel system documentation includes metal composite panels, aluminum plate, precast concrete, stone cladding, terracotta, fiber cement, and rainscreen assemblies. We also provide detailed shop drawings for specialty facade elements including sunshades, decorative features, canopies, and entry systems. Beyond standard systems, our services address custom facade components, hybrid assemblies combining multiple systems, historic reproduction elements, and geometrically complex enclosures with unique fabrication requirements. This comprehensive capability ensures we can document any facade system from standard configurations to unique architectural expressions.

Our Facade Shop Drawings provide manufacturing-level detail with complete fabrication and installation information tailored to specific system requirements. Typical documentation includes overall assembly drawings showing component relationships and key dimensions, detailed part drawings with precise profiles and dimensions for each unique element, and connection details showing exact joint configurations, fastener specifications, and assembly methods. Material specifications detail exact alloys, finishes, treatments, and performance requirements for all components. Comprehensive hardware schedules document fasteners, anchors, gaskets, and accessories with appropriate part numbers and specifications. System-specific information includes glazing details, pressure equalization provisions, drainage paths, and thermal breaks. Installation documentation provides anchor layouts, mounting details, sequencing instructions, and tolerance management approaches. For complex systems, we include detailed assembly plans, piece identification systems, and tracking schedules to support manufacturing and field installation.

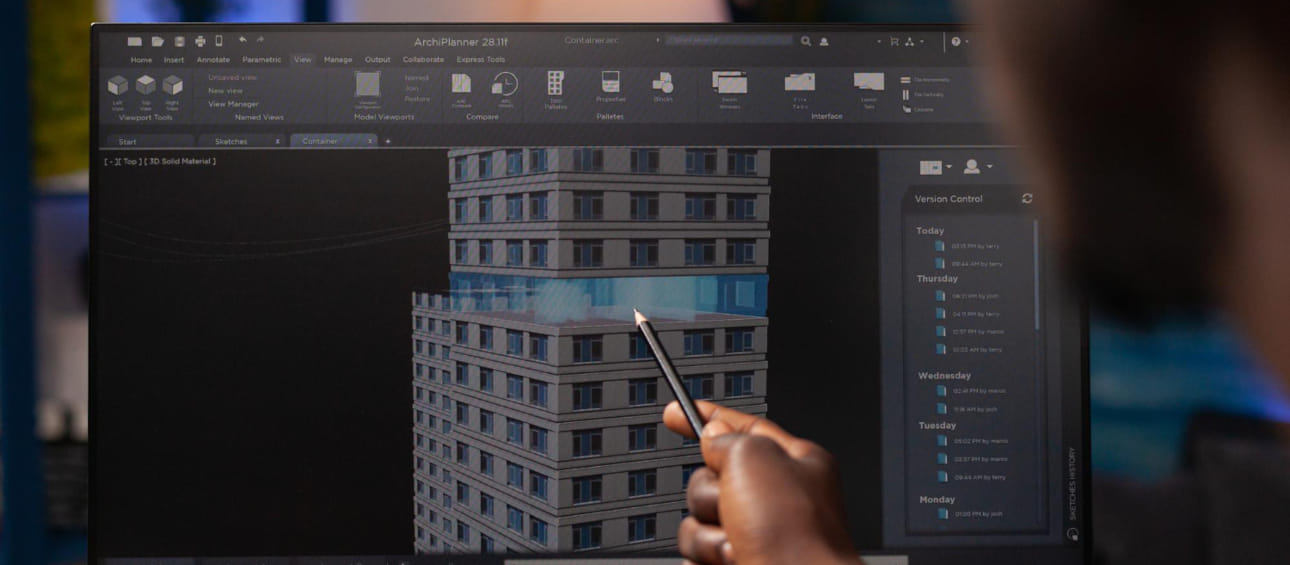

Our Facade Shop Drawing development follows a structured methodology that ensures manufacturing-ready documentation. The process begins with comprehensive review of architectural design documents, performance specifications, and system requirements to establish documentation parameters. For manufacturer-specific systems, we confirm standard details, catalog components, and system limitations that inform the documentation approach. Initial development focuses on critical dimensions, primary components, and key interfaces with approval drawings that validate the general approach. Once approved, we proceed with detailed development of all system components, connection details, and assembly information with appropriate manufacturing references and industry standards. Throughout development, we maintain rigorous quality control procedures including dimensional verification, standards compliance, and constructability review. The completed documentation undergoes comprehensive checking procedures before submission for approval, with revision management systems that track changes through the review process until final acceptance.

We implement comprehensive coordination processes that ensure facade shop drawings properly integrate with all adjacent building systems. For structural coordination, we verify embedment locations, anchor points, and load transfer mechanisms with detailed interface documentation showing the exact relationship between facade anchors and structural elements. This includes appropriate tolerance accommodation, adjustment provisions, and load path verification that ensures proper structural support. For interface with other building systems, we document transition details, weatherproofing continuity, and integration requirements between the facade and adjacent construction including roofing, waterproofing, interior finishes, and MEP penetrations. Throughout the documentation process, we maintain systematic clash detection and spatial verification to identify potential conflicts between facade components and other building elements, ensuring all systems work together seamlessly for successful implementation.

Complex geometry and custom facade elements require specialized documentation approaches that we have refined through extensive experience. For curved and non-orthogonal facades, we implement sophisticated geometric control systems with precise dimensional references, control point networks, and parametric relationships that accurately define complex surfaces. Panelization strategies are documented with detailed layout plans showing exact panel dimensions, joint configurations, and support locations optimized for both visual appearance and fabrication efficiency. For custom elements, we develop comprehensive manufacturing documentation with detailed profiles, assembly methods, and fabrication sequences appropriate to the material and manufacturing process. Throughout documentation, we emphasize geometric rationalization strategies that maintain design intent while accommodating fabrication constraints, material limitations, and installation realities. For highly complex elements, we supplement traditional documentation with 3D manufacturing models, digital fabrication data, and assembly simulations that support advanced production methods.

Our Facade Shop Drawings incorporate comprehensive quality control provisions that support verification throughout fabrication and installation processes. For manufacturing quality control, the documentation includes critical dimension references, tolerance specifications, and inspection criteria for each component. Material verification procedures detail required testing, certification requirements, and acceptance standards to ensure compliance with performance specifications. Assembly verification documentation provides quality check points, fit-up verification methods, and testing protocols for fabricated assemblies. For field installation, our documentation includes layout control references, anchor verification procedures, and alignment checking methods that ensure proper positioning. Progressive installation verification details critical inspection stages, concealed condition documentation requirements, and performance testing protocols. Throughout all documentation, we incorporate industry standard quality references, manufacturer recommendations, and project-specific requirements that establish clear quality expectations and verification methodologies for all facade components.

Our Facade Shop Drawing services provide comprehensive deliverables tailored to specific project requirements and fabrication workflows. Standard documentation packages include detailed drawing sets with elevation control plans, component layouts, assembly details, part drawings, connection details, and installation instructions organized according to industry conventions. These are supplemented by comprehensive bills of materials, hardware schedules, finish schedules, and glazing schedules that detail all required components. Technical submittals include product data, performance certifications, engineering calculations, and testing documentation that support system approval. Deliverable formats include both hard copy printing at appropriate scales and digital files in multiple formats including native CAD (typically DWG), PDF sets at production-ready resolution, and specialized formats for manufacturing equipment where required. For digital fabrication, we can provide CNC-ready files, 3D manufacturing models, and production data in formats compatible with automated manufacturing systems. All deliverables undergo comprehensive quality review before release, with detailed checking documentation that verifies completion and accuracy.

Wide Range of SERVICES

Other Façade Modeling

Browse our specialized facade modeling services that provide detailed design, documentation, and fabrication support for complex building envelope systems.

Create detailed BIM models of building facades and envelope systems, supporting design development, analysis, and construction documentation.

Create detailed drawings and models for curtain wall systems, including mullions, transoms, glazing, connections, and weatherproofing details.