MEP BIM Modeling Services

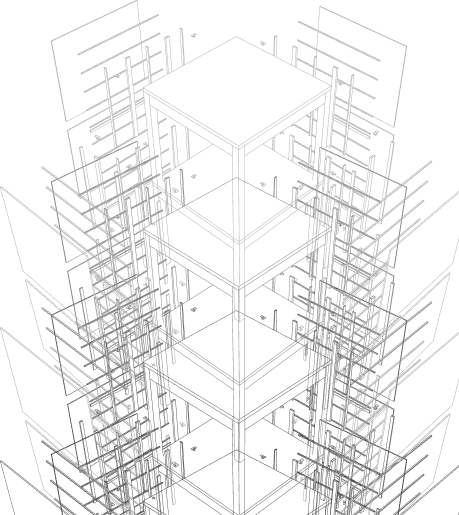

In contemporary building design and construction, MEP BIM Modeling has transformed how mechanical, electrical, and plumbing systems are designed, coordinated, and implemented. Our specialized services create detailed 3D models of building systems with comprehensive component information, spatial coordination, and performance data. These intelligent models serve as complete digital prototypes that enable virtual construction and testing before physical implementation, significantly improving coordination, optimizing performance, and enhancing construction efficiency for these complex and critical building systems.

Building Systems BIM

- Comprehensive 3D modeling of mechanical, electrical, and plumbing systems

- Detailed component representation with accurate dimensions and specifications

- Complete system coordination and clash detection with building elements

Comprehensive MEP BIM Solutions

Our MEP BIM Modeling services deliver detailed digital representations of building systems through intelligent 3D models that define both physical components and system functionality. We create comprehensive models for mechanical systems (HVAC equipment, ductwork, piping), electrical systems (power distribution, lighting, low voltage), and plumbing systems (water supply, sanitary, storm drainage) with appropriate detail levels and component information. Each system is modeled with accurate dimensions, proper specifications, and complete distribution networks that establish spatial requirements, connection relationships, and performance characteristics for all building services.

Beyond geometric representation, our MEP models incorporate intelligence that defines how systems function and interact. Equipment components include performance specifications, connection requirements, and service clearances that support both engineering analysis and installation planning. Distribution elements contain sizing information, flow data, and system relationships that establish functional connections between components. Throughout the model, appropriate annotation, identification, and parameter information creates a complete digital prototype that supports diverse applications from design validation through construction implementation and into building operations. This comprehensive approach transforms MEP documentation from simple drawings into intelligent system models that improve coordination, enhance performance, and support efficient construction throughout the project lifecycle.

Strategic Benefits of MEP BIM Modeling

Implementing MEP BIM Modeling delivers substantial advantages throughout the design, construction, and operation of building systems. During design development, the comprehensive digital representation enables better engineering decisions through visual analysis, system simulation, and performance validation that optimize both capacity specifications and distribution efficiency. The 3D coordination capability identifies spatial conflicts between systems and building elements before construction, preventing costly field collisions, redesign requirements, and installation delays that typically impact MEP installation. These proactive coordination processes typically reduce change orders by 40-60% and field conflicts by 50-80% compared to traditional documentation methods.

During construction implementation, MEP BIM models support enhanced fabrication and installation processes that significantly improve field efficiency. The detailed component information enables prefabrication of distribution assemblies, accurate material procurement, and precise installation planning that accelerate construction schedules while improving quality. Installation teams benefit from visual documentation, clear spatial understanding, and comprehensive system information that reduces field questions, improves assembly accuracy, and enhances overall construction efficiency. Throughout building operations, the detailed system documentation provides valuable reference information for maintenance procedures, system modifications, and performance optimization that extends these benefits throughout the entire building lifecycle.

Industry Applications of MEP BIM Modeling

Healthcare Facilities

Specialized MEP BIM modeling for hospitals, medical centers, and healthcare environments with complex system requirements. Our healthcare MEP modeling addresses critical systems including medical gas, specialized ventilation, emergency power, isolation environments, and equipment integration with proper coordination and regulatory compliance. These comprehensive models support the demanding technical requirements of healthcare facilities while ensuring reliability, redundancy, and performance for these mission-critical installations.

Data Centers & Mission Critical

Advanced MEP BIM modeling for data centers, telecommunications facilities, and mission-critical installations with high-reliability requirements. Our critical facility models address cooling systems, power distribution, redundancy provisions, monitoring infrastructure, and specialized systems with exacting detail and performance specifications. These detailed models support the operational imperatives of critical environments including continuous uptime, capacity requirements, and maintenance planning while ensuring maximum system reliability and performance.

Laboratory & Research Facilities

Comprehensive MEP BIM modeling for research laboratories, scientific facilities, and specialized technical environments with complex system requirements. Our laboratory MEP models document fume hood systems, specialized exhaust, research gases, pure water systems, and equipment integration with appropriate safety provisions and performance specifications. These detailed models support the unique technical requirements of research environments while ensuring compliance, safety, and appropriate system performance for sensitive operations.

Commercial & Mixed-Use Development

Efficient MEP BIM modeling for commercial buildings, office developments, and mixed-use projects with diverse system requirements. Our commercial MEP models address central plants, distribution systems, tenant provisions, and integrated controls with appropriate zoning and flexibility considerations. These comprehensive models support the economic imperatives of commercial developments including efficient implementation, optimized performance, and flexible adaptation while enabling effective coordination and construction of these complex projects.

Why Choose Us

Advanced MEP BIM Solutions That Enhance Building System Performance

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

MEP BIM Modeling is the specialized development of detailed 3D models for mechanical, electrical, and plumbing systems with comprehensive component information, spatial coordination, and performance data. Unlike traditional 2D documentation, MEP BIM creates intelligent digital representations where each component contains parametric intelligence, engineering attributes, and connection relationships that define how systems function. This approach enhances building system design and construction in multiple ways: spatial coordination identifies conflicts between systems before installation; system sizing optimization ensures proper capacity and efficient material use; prefabrication becomes possible through accurate digital prototyping; installation efficiency improves through clear 3D visualization; and design validation confirms performance requirements are met before construction. The comprehensive digital representation created through MEP BIM provides a complete system prototype that enables virtual construction and testing before physical implementation, significantly reducing field conflicts, improving construction efficiency, and enhancing overall building system performance.

Our MEP BIM services address comprehensive building systems and components across all disciplines. For mechanical systems, we model HVAC equipment including air handling units, VAV boxes, heat exchangers, chillers, boilers, fans, and pumps with all distribution components including ducts, pipes, dampers, valves, and terminal units. Electrical modeling includes service equipment, transformers, switchgear, panels, generators, UPS systems, and distribution infrastructure with comprehensive lighting systems, receptacles, and specialty electrical components. Plumbing models include water distribution, sanitary systems, storm drainage, specialty piping, and fixture connections with appropriate system definition. Fire protection documentation covers sprinkler systems, standpipes, fire pumps, and alarm components with code-compliant coverage representation. Additional systems include building controls, low voltage installations, specialty medical or lab systems, renewable energy components, and site utilities as required. Each system is modeled with appropriate level of detail, component intelligence, and performance attributes specified by project requirements, creating comprehensive digital representations of complete building systems from major equipment through distribution networks to terminal devices.

Our MEP BIM models provide flexible detail levels calibrated to project phase and application requirements. For concept and schematic design (LOD 100-200), we develop diagrammatic system representation with primary equipment, major distribution routes, and space allocation to support early coordination and concept validation. During design development (LOD 300), models include accurate equipment dimensions, properly sized distribution, defined clearances, and specific components with connection requirements and performance parameters. For construction documentation (LOD 350-400), comprehensive models incorporate complete distribution layouts, detailed component specification, hanger and support systems, insulation requirements, and fabrication-level detail for major elements with appropriate annotation and identification. Shop drawing models (LOD 400) include fabrication-specific information with detailed manufacturing requirements, assembly instructions, and installation data optimized for prefabrication. The appropriate detail level is established through project requirements analysis, ensuring models provide necessary information without excessive detail when not required. Throughout all detail levels, our models maintain component intelligence, system relationships, and performance attributes that support analysis, coordination, and construction planning beyond simple geometric representation.

Comprehensive coordination between MEP systems and other building elements is a fundamental aspect of our modeling approach. We implement systematic clash detection processes that identify spatial conflicts between MEP components and structural elements, architectural features, equipment, and other building systems. These detection protocols employ appropriate clearance parameters, priority hierarchies, and resolution workflows that address conflicts according to project requirements. Beyond simple clash identification, our coordination approach includes routing optimization that develops efficient system pathways while respecting architectural and structural constraints. For critical areas including mechanical rooms, ceiling plenums, vertical shafts, and congested spaces, we implement enhanced coordination processes with detailed component modeling, explicit sequence planning, and installation verification. Throughout the coordination process, our team maintains comprehensive documentation of identified issues, resolution approaches, and verification confirmation that establishes clear records of coordination outcomes. This systematic approach ensures all MEP systems integrate properly with building elements, address spatial constraints appropriately, and maintain necessary clearances for installation, operation, and maintenance throughout the facility.

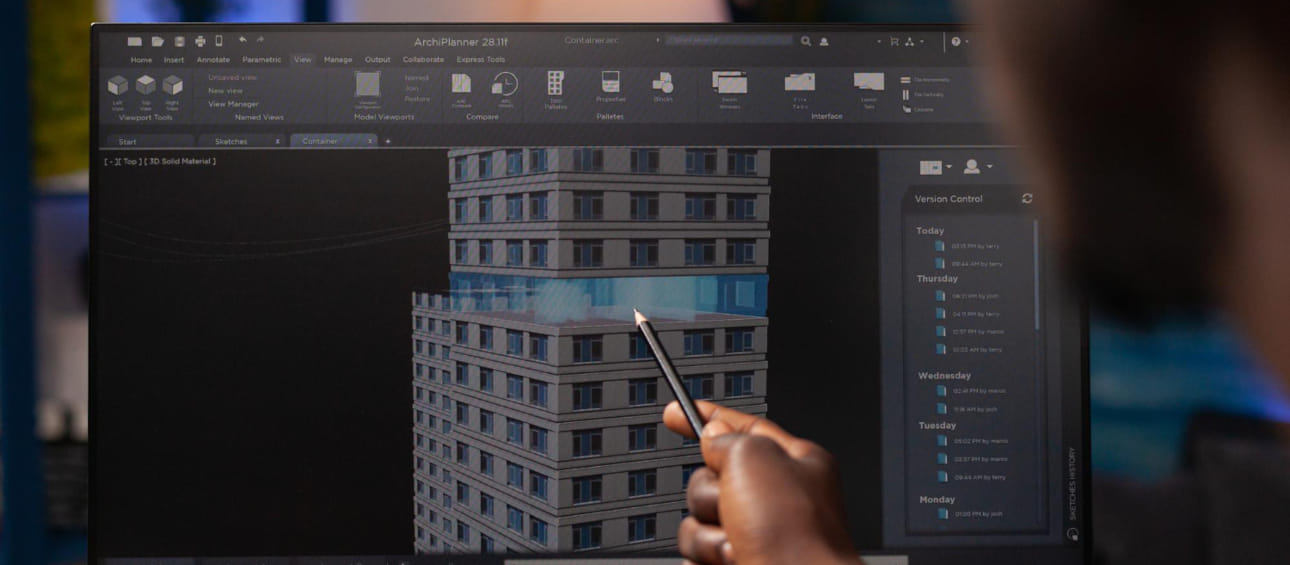

We employ industry-leading software platforms and technologies tailored to MEP BIM requirements and project workflows. Our primary modeling environments include Autodesk Revit MEP with specialized system templates, content libraries, and workflow enhancements optimized for mechanical, electrical, and plumbing applications. For advanced applications, we utilize specialized tools including Autodesk Fabrication CADmep for detailed manufacturing modeling, SysQue for enhanced component development, and AutoCAD MEP for specific workflow requirements. These platforms are supplemented by analysis tools including energy modeling software, pipe stress analysis applications, electrical sizing programs, and lighting simulation tools that integrate with modeling workflows. For coordination, we implement Navisworks, BIM 360, and Solibri with customized rule sets and review protocols specifically calibrated for MEP system requirements. Our technology ecosystem is continuously updated to incorporate emerging tools including computational design applications, prefabrication interfaces, and advanced analysis capabilities that enhance both efficiency and quality in MEP modeling, ensuring optimal outcomes regardless of project complexity or specialized requirements.

Our MEP BIM models provide comprehensive support for fabrication and installation through specialized development approaches that enhance construction efficiency. For fabrication processes, models include manufacturing-ready component information with precise dimensions, connection details, material specifications, and assembly requirements that support direct production from digital information. Specialized spool drawings, fabrication sheets, and assembly documentation are extracted directly from models with appropriate dimensioning, tagging, and identification systems that streamline shop production. When prefabrication is implemented, models define module boundaries, connection interfaces, and assembly sequences with transport and rigging information that supports efficient manufacturing and field assembly. For installation planning, models provide detailed layout information, hanger positions, support requirements, and mounting details with appropriate sequencing information to guide field implementation. Throughout construction, installation validation protocols compare as-built conditions to modeled systems, identifying discrepancies and supporting quality assurance processes. This comprehensive approach transforms MEP models from design documentation into complete digital construction resources that substantially improve fabrication accuracy, installation efficiency, and overall construction quality for building systems.

Our MEP BIM models provide extensive support for performance analysis and energy efficiency through integrated engineering intelligence and simulation capabilities. For load analysis, models incorporate accurate space definitions, envelope characteristics, occupancy parameters, and usage patterns that enable precise calculation of heating, cooling, and electrical requirements with appropriate diversity factors and safety margins. Energy performance evaluation utilizes system specifications, equipment efficiency ratings, distribution properties, and control strategies to simulate building consumption, identify optimization opportunities, and validate efficiency measures. For specialized analysis, models provide airflow simulation data, electrical distribution parameters, pipe sizing information, and equipment performance metrics that support detailed engineering evaluation and system optimization. The intelligent nature of BIM components enables real-time performance updates when design changes occur, allowing immediate assessment of modification impacts on system efficiency and capacity requirements. Throughout design development, these analysis capabilities support data-driven decision-making, engineering optimization, and performance validation that enhance overall building efficiency and system effectiveness before construction begins, significantly improving both initial system design and long-term operational performance.

Our MEP BIM modeling services provide comprehensive deliverables tailored to project requirements and implementation workflows. Standard model deliverables include native BIM files (typically Revit) with properly organized system structures, component hierarchies, and parameter organizations optimized for project applications. These models are supplemented by coordination deliverables including clash detection reports, resolution documentation, and verified spatial validation that confirm system integration. Documentation extractions include traditional 2D drawings with plans, sections, elevations, and details containing appropriate annotation, dimensioning, and technical information. For analysis applications, we provide performance reports, load calculations, and system evaluations derived directly from model data. Fabrication deliverables include shop drawings, spool sheets, and manufacturing documentation optimized for production processes. For field implementation, installation drawings, layout plans, and mounting details guide construction activities with appropriate information hierarchy. When facility management applications are required, we provide equipment inventories, maintenance access documentation, and system information structured for operational use. All deliverables include appropriate metadata, project information, and organizational structure that supports effective implementation across diverse project applications from design validation through construction and into building operations.

Wide Range of SERVICES

Other MEP BIM Services

Browse our specialized mechanical, electrical, and plumbing design services that ensure optimal building system performance, efficiency, and integration.

Coordinate mechanical, electrical, and plumbing systems to resolve conflicts and optimize space utilization within building environments.

Develop detailed fabrication and installation drawings for mechanical, electrical, and plumbing systems based on coordinated BIM models.

Create precise technical drawings for mechanical, electrical, and plumbing systems, including plans, sections, and details for construction.

Model site and building utilities including water, sewer, stormwater, and energy systems for improved coordination and construction planning.