MEP Coordination Services

In modern construction, MEP Coordination has become essential for successful project delivery, transforming how mechanical, electrical, and plumbing systems integrate with building architecture and structure. Our specialized coordination services create virtually constructed environments where all building systems are properly aligned and integrated before field installation begins. This proactive approach identifies and resolves spatial conflicts during design, preventing costly field issues, optimizing system layout, and significantly enhancing construction efficiency for these complex and interdependent building systems.

MEP System Integration

- Systematic coordination of mechanical, electrical, and plumbing systems

- Comprehensive clash detection and resolution before construction begins

- Multi-discipline integration for optimal space utilization and system efficiency

Comprehensive MEP Coordination Approach

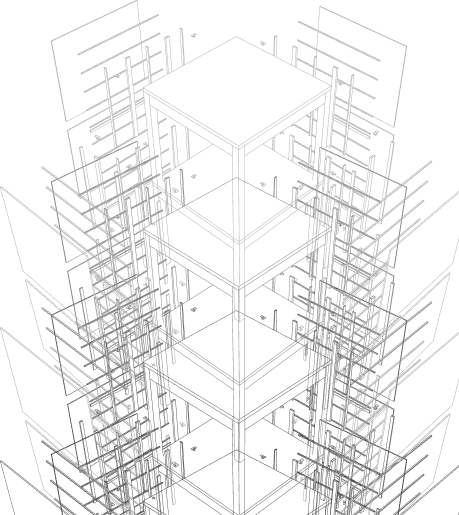

Our MEP Coordination services implement a structured methodology that systematically integrates building systems through collaborative 3D modeling and conflict resolution. We begin with coordination planning that establishes technical requirements, system priorities, and resolution hierarchies based on project complexity and construction sequencing. Using comprehensive BIM modeling, we develop accurate digital representations of all systems including mechanical components (equipment, ductwork, piping), electrical infrastructure (distribution, lighting, low voltage), and plumbing networks (supply, sanitary, fire protection) with proper sizing, clearance requirements, and operational characteristics.

The formal coordination process proceeds through defined building zones in logical sequence, with focused attention on equipment rooms, vertical risers, and congested areas where conflicts are most prevalent. For each zone, our systematic clash detection identifies spatial conflicts using appropriate tolerance settings and system hierarchies, followed by collaborative resolution sessions where engineering teams collectively determine optimal solutions. These solutions are implemented in the respective discipline models, verified for effectiveness, and documented for project reference. This cyclical process continues until all building systems are fully coordinated, resulting in a comprehensive virtual construction model that validates spatial integration before physical implementation begins, significantly reducing field conflicts, enhancing installation efficiency, and improving overall construction outcomes.

Strategic Benefits of MEP Coordination

Implementing comprehensive MEP Coordination delivers substantial advantages throughout design, construction, and building operations. The most significant benefit comes through proactive conflict prevention, where identifying and resolving system clashes during design eliminates costly field conflicts that typically require rework, material waste, design revisions, and schedule delays when discovered during construction. Industry research shows that resolving conflicts during coordination typically costs 5-15 times less than addressing them in the field, with projects experiencing 70-90% fewer MEP-related RFIs and substantially reduced change orders.

Beyond conflict prevention, coordination optimizes system layout and space utilization through collaborative planning that improves both installation efficiency and operational performance. The detailed spatial understanding enables prefabrication opportunities, accurate material quantification, and precise installation planning that collectively accelerate construction schedules while improving quality. For construction teams, the coordinated model provides clear visualization, detailed understanding, and precise layout information that significantly enhances field productivity and installation accuracy. These benefits typically reduce overall MEP installation costs by 8-12%, compress installation schedules by 15-25%, and substantially improve system quality compared to uncoordinated projects, delivering significant value throughout construction and building operation.

Industry Applications of MEP Coordination

Healthcare Facilities

Specialized MEP coordination for hospitals, medical centers, and healthcare environments with highly complex and interdependent systems. Our healthcare coordination addresses critical integration requirements including medical gas systems, isolation room pressurization, emergency power distribution, specialized equipment services, and infection control considerations. This meticulous coordination ensures proper functionality, compliance with stringent regulations, and operational reliability for these mission-critical facilities where system performance directly impacts patient care and safety.

Commercial Office Developments

Efficient MEP coordination for office buildings, corporate headquarters, and mixed-use developments with diverse tenant requirements. Our commercial coordination optimizes base building systems, tenant distribution infrastructure, and vertical services with flexibility provisions that accommodate future modifications and tenant improvements. This systematic approach improves both construction efficiency and long-term operational adaptability while ensuring proper integration between core systems and tenant build-outs throughout these dynamic environments.

Data Centers & Mission Critical

Comprehensive MEP coordination for data centers, telecommunications facilities, and mission-critical installations with redundant system requirements. Our critical facility coordination addresses cooling infrastructure, power distribution, backup systems, monitoring networks, and physical security with exacting precision and reliability considerations. This intensive coordination ensures operational continuity, system redundancy, and maintenance access while optimizing the dense equipment and infrastructure arrangement that characterizes these highly technical environments.

Educational & Institutional Projects

Specialized MEP coordination for educational facilities, research buildings, and institutional projects with varied program requirements. Our institutional coordination addresses diverse system needs including laboratory services, classroom environments, assembly spaces, and administrative functions within unified building infrastructure. This holistic approach ensures proper system performance across different functional areas while optimizing installation efficiency, maintenance access, and operational flexibility throughout these complex, multi-purpose facilities.

Why Choose Us

Advanced MEP Coordination Solutions That Improve Building System Integration

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

MEP Coordination is the systematic process of integrating mechanical, electrical, and plumbing systems with each other and with architectural and structural elements to eliminate spatial conflicts before construction. Unlike traditional siloed design approaches, MEP coordination uses 3D modeling and clash detection to create a virtually constructed environment where all building systems are properly aligned and integrated. This process is essential because modern buildings contain increasingly complex and dense systems that must coexist within limited spatial constraints. Without proper coordination, field conflicts inevitably arise during construction, resulting in rework, delays, change orders, and cost overruns. Studies show that effective MEP coordination typically reduces construction RFIs by 60-80%, minimizes change orders by 40-50%, and can decrease installation time by 15-25% compared to uncoordinated projects. Beyond avoiding conflicts, coordination optimizes system routing, ensures proper maintenance access, validates performance requirements, and creates installation efficiency that significantly enhances project delivery outcomes for all stakeholders.

The MEP coordination process follows a structured methodology that systematically integrates building systems through collaborative 3D modeling and conflict resolution. The process begins with coordination planning that establishes priorities, sequences, responsibilities, and technical requirements for model development. Initial model creation then develops accurate 3D representations of each system with proper component sizing, clearance requirements, and spatial characteristics. The formal coordination workflow proceeds through defined building zones in a logical sequence, typically starting with major equipment rooms, vertical risers, and congested ceiling areas where conflicts are most prevalent. For each zone, clash detection processes identify spatial conflicts using appropriate tolerance settings and system hierarchies, followed by collaborative resolution sessions where engineering teams collectively determine optimal solutions for identified issues. Approved resolutions are implemented in the respective discipline models, verified for effectiveness, and documented for project reference. This cyclical process continues through all building zones until systems are completely coordinated, resulting in a comprehensive 'virtual construction' that validates spatial integration before field implementation. Throughout this process, detailed documentation tracks all identified conflicts, resolution methods, and implementation verification to establish a clear record of coordination outcomes. The effectiveness of this process depends on appropriate model detail, cross-discipline collaboration, systematic conflict management, and consistent verification protocols that collectively ensure all building systems will properly integrate during actual construction.

Our MEP coordination services address comprehensive building systems integration across all disciplines and components. Primary mechanical systems include HVAC ductwork with appropriate insulation dimensions, piping networks with proper slopes and insulation, and equipment with accurate dimensions and service clearances. Electrical coordination includes distribution systems (conduit, cable tray, busway), lighting elements, and equipment with connection requirements and access spaces. Plumbing and fire protection systems encompass all distribution piping, fixtures, equipment, and specialized components with accurate sizing and slope representations. Beyond traditional MEP systems, our coordination integrates specialty components including medical gas infrastructure, laboratory services, process systems, pneumatic networks, and building controls. These systems are coordinated not only with each other but with architectural elements (ceilings, walls, soffits, fixtures), structural components (beams, columns, bracing, decking), and building envelope systems to ensure complete spatial compatibility. Our process also incorporates transport systems, specialty equipment, access requirements, and maintenance clearances that extend beyond simple clash detection to address operational functionality. This comprehensive approach ensures all building systems and components are properly integrated spatially, functionally, and operationally before construction begins.

MEP coordination delivers substantial cost and schedule benefits through proactive conflict prevention and optimized installation planning. The primary financial impact comes through preemptive conflict resolution, where identifying and addressing system clashes during design prevents costly field conflicts that typically require rework, material waste, design revisions, and schedule delays when discovered during construction. Industry studies consistently show that resolving a conflict in the field costs 5-15 times more than addressing it during design coordination, with the average MEP field conflict costing between $3,000-$15,000 to resolve depending on complexity. Beyond direct conflict costs, coordination enables optimized material procurement through accurate quantity extraction, reduced installation contingencies, and minimized waste factors that significantly improve project economics. Schedule benefits derive from streamlined installation processes where field crews can work efficiently without unexpected conflicts, impromptu design revisions, or coordination delays. The highly visualized nature of coordination models also improves installation planning, enables prefabrication opportunities, and enhances crew productivity through clear spatial understanding. Collectively, these benefits typically reduce overall MEP installation costs by 8-12% and compress installation schedules by 15-25% compared to uncoordinated projects, delivering significant economic advantages alongside improved quality and reduced risk throughout construction implementation.

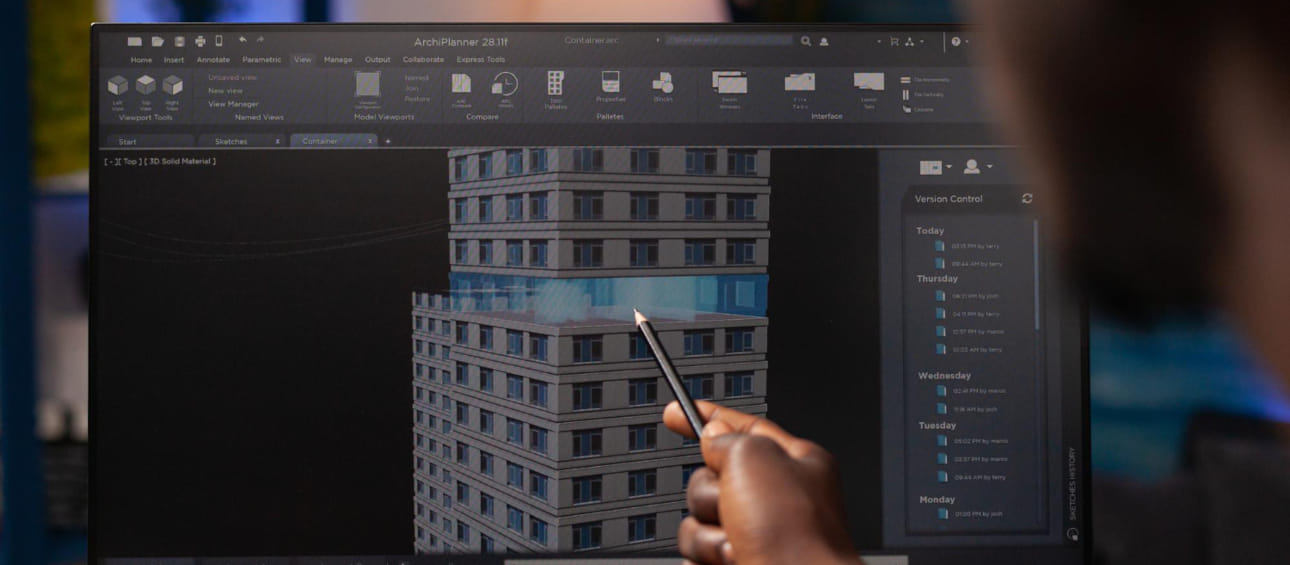

Our MEP coordination implements industry-leading technologies and platforms optimized for effective system integration and conflict resolution. For model development and discipline-specific content, we utilize Autodesk Revit MEP with specialized templates, content libraries, and system configurations that ensure appropriate detail levels and component intelligence across all disciplines. These base models integrate with structural and architectural platforms through standardized exchange protocols that maintain accuracy and fidelity during collaboration. For dedicated coordination activities, we employ advanced platforms including Autodesk Navisworks Manage, BIM 360 Coordinate, and Autodesk Construction Cloud with customized rule sets, tolerance configurations, and reporting templates specifically calibrated for MEP system requirements. These platforms support systematic clash detection, issue tracking, resolution management, and verification documentation throughout the coordination process. To enhance visualization and communication, we implement specialized viewing technologies including web-based model access, VR/AR applications for immersive spatial evaluation, and field-deployed mobile solutions that extend coordination benefits to construction implementation. This technology ecosystem continuously evolves to incorporate emerging tools including automated clash resolution algorithms, machine learning applications, and enhanced visualization capabilities that maximize coordination effectiveness regardless of project complexity or specialized system requirements.

MEP coordination provides essential foundations for prefabrication and modular construction through precise spatial definition and system integration that enables off-site manufacturing approaches. The detailed 3D coordination model establishes exact positions, routing paths, and connection points for all system components with dimensional accuracy that supports manufacturing-level precision in prefabricated assemblies. This spatial certainty enables the development of multi-trade racks, corridor modules, equipment skids, and bathroom pods with confidence that these elements will properly integrate during field installation. Beyond simple spatial definition, coordination processes identify ideal module boundaries, connection interfaces, and assembly transitions that optimize prefabrication opportunities while maintaining system functionality. The coordination platform also supports digital handoff between design and manufacturing teams, providing accurate dimensional data, material specifications, and assembly information directly to fabrication facilities. Throughout implementation, coordinated models enable precise quality control, dimensional verification, and installation validation that ensures prefabricated elements properly integrate with field-installed systems. This comprehensive approach transforms coordination from simple collision avoidance into a manufacturing-focused process that enables modular construction approaches, enhances production efficiency, improves installation quality, and accelerates overall construction schedules through optimized off-site fabrication strategies.

Our coordination methodology implements structured change management protocols that maintain system integration throughout design evolution and scope modifications. When design changes occur, we employ systematic impact analysis processes that evaluate modification effects across all disciplines, identifying new conflict potentials, clearance issues, and integration requirements before implementation. Change implementation follows controlled procedures where updates are synchronized across discipline models, verified for coordination impact, and validated through focused clash detection to ensure continued spatial compatibility. For significant changes, dedicated coordination sessions address specific modification areas with cross-discipline participation to develop integrated solutions that maintain system functionality while preserving spatial coordination. Throughout this process, comprehensive documentation tracks change origins, coordination impacts, resolution approaches, and verification outcomes to maintain clear project records. This structured approach accommodates design evolution while preserving coordination integrity, preventing the degradation of system integration that frequently occurs when changes are implemented without proper coordination validation. By maintaining coordination rigor throughout design development, even projects with substantial scope evolution maintain the benefits of comprehensive system integration from initial concept through final construction implementation.

Our MEP coordination services provide comprehensive deliverables that document system integration and support effective construction implementation. The primary coordination deliverable is a fully integrated multi-discipline model where all systems have been spatially coordinated, conflicts resolved, and clearances verified according to project requirements. This model is accompanied by detailed clash reports that document all identified conflicts, resolution methods, and verification confirmations with appropriate screenshots, location references, and technical descriptions. Coordination worksheets provide zone-by-zone tracking of system integration status, responsibility assignments, and resolution verification that establishes a clear record of completion. For construction implementation, we provide coordinated shop drawings that reflect resolved system layouts with appropriate dimensioning, annotation, and installation references derived directly from the coordinated model. These drawings include composite views of integrated systems in congested areas where installation sequence and spatial understanding are critical. When prefabrication is implemented, coordination deliverables include specialized fabrication documentation with precise dimensional information and assembly details. Additional deliverables include coordination meeting minutes, resolution logs, and technical documentation that establish a comprehensive record of the coordination process. All deliverables are organized in standardized formats with consistent nomenclature, clear identification, and accessible structure that supports effective utilization throughout construction implementation.

Wide Range of SERVICES

Other MEP BIM Services

Browse our specialized mechanical, electrical, and plumbing design services that ensure optimal building system performance, efficiency, and integration.

Create detailed BIM models for mechanical, electrical, and plumbing systems, ensuring proper integration with architectural and structural elements.

Develop detailed fabrication and installation drawings for mechanical, electrical, and plumbing systems based on coordinated BIM models.

Create precise technical drawings for mechanical, electrical, and plumbing systems, including plans, sections, and details for construction.

Model site and building utilities including water, sewer, stormwater, and energy systems for improved coordination and construction planning.