MEP Shop Drawing Services

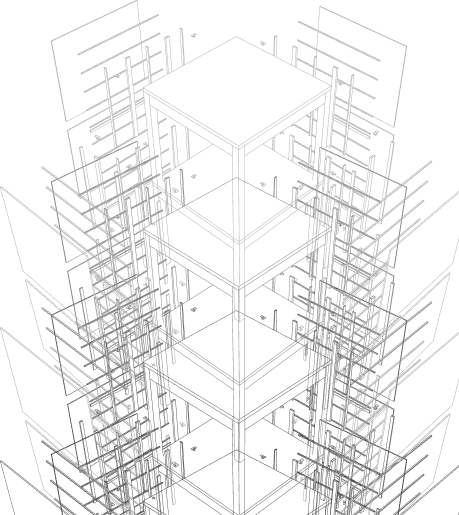

In modern construction, MEP shop drawings have become essential for successful system implementation, transforming design concepts into precise fabrication and installation documentation. Our specialized shop drawing services create detailed documentation for mechanical, electrical, and plumbing systems that bridge the gap between engineering intent and physical construction. These comprehensive drawings provide the specific dimensions, connections, and installation details needed for efficient fabrication, accurate installation, and quality construction of these complex building systems.

System Documentation

- Detailed fabrication and installation drawings for mechanical, electrical, and plumbing systems

- Precise dimensional documentation with component-specific information

- Comprehensive construction documentation derived from coordinated BIM models

Comprehensive MEP Shop Drawing Development

Our MEP shop drawing services implement a structured development process that transforms design intent into detailed fabrication and installation documentation. We begin with comprehensive design analysis to evaluate engineering requirements, specifications, and construction parameters while identifying areas requiring further development. Based on this analysis, we develop coordinated models that integrate with architectural constraints, structural elements, and other building systems to establish conflict-free spatial arrangements that optimize system installation. These models incorporate specific manufacturer components, connection details, support systems, and installation requirements based on approved submittals and contractor preferences.

From these detailed models, we produce comprehensive documentation including plans, sections, elevations, and details with proper dimensioning, tagging, and annotations that guide fabrication and field installation. Our documentation includes specific fabrication information such as material specifications, connection types, reinforcement requirements, and assembly instructions tailored to production processes. For field implementation, drawings provide installation parameters including mounting details, hanger locations, routing dimensions, and connection requirements with clear reference points and established datums. Throughout this process, systematic quality control, coordination verification, and dimensional validation ensure the final documentation accurately represents both design intent and construction requirements while addressing the specific needs of fabrication teams and field installers.

Strategic Benefits of MEP Shop Drawings

Implementing comprehensive MEP shop drawings delivers substantial advantages throughout fabrication, installation, and construction management. The primary benefit comes through improved construction efficiency, where detailed documentation enables prefabrication of system components, precise material procurement, and optimized installation planning that collectively accelerate construction timelines while enhancing quality. For fabrication teams, the detailed component information supports shop manufacturing with specific dimensions, connection details, and assembly requirements that improve production efficiency and component accuracy.

During field installation, comprehensive documentation provides precise location information, mounting details, and connection requirements that reduce field interpretation, improve crew productivity, and enhance installation quality. This documentation clarity typically reduces field questions by 50-70%, installation errors by 40-60%, and rework requirements by 30-40% compared to projects without detailed shop drawings. For project management, the documentation improves planning accuracy, resource allocation, and schedule development while providing clear references for quality control and inspection processes. These benefits collectively reduce overall MEP installation costs by 10-15%, accelerate installation timelines by 15-25%, and significantly improve system quality, delivering substantial advantages throughout construction while providing valuable reference documentation for future operations and maintenance.

Industry Applications of MEP Shop Drawings

Healthcare Facilities

Specialized MEP shop drawings for hospitals, medical centers, and healthcare environments with complex system requirements. Our healthcare documentation addresses critical components including medical gas systems, isolation room controls, specialized equipment connections, and contamination prevention measures with exacting detail and compliance verification. These comprehensive drawings ensure proper installation of life-safety systems, infection control measures, and specialized medical infrastructure while supporting the demanding construction requirements of these regulated environments.

Data Centers & Mission Critical

Detailed MEP shop drawings for data centers, telecommunications facilities, and mission-critical installations with high-reliability requirements. Our documentation for critical facilities addresses power distribution, cooling systems, redundant infrastructure, monitoring networks, and emergency systems with precise installation requirements and testing provisions. These specialized drawings support the construction of fault-tolerant systems, continuous operations infrastructure, and maintenance-friendly installations essential for mission-critical facility performance and reliability.

Industrial & Manufacturing

Comprehensive MEP shop drawings for industrial facilities, manufacturing plants, and process installations with specialized system requirements. Our industrial documentation addresses process services, equipment connections, utility distribution, and production support systems with appropriate construction details and installation specifications. These detailed drawings support efficient implementation of complex industrial systems while ensuring proper integration with production equipment, material handling operations, and manufacturing processes in these demanding environments.

Multi-Family & High-Rise Development

Efficient MEP shop drawings for residential towers, apartment complexes, and multi-family developments with repeated system requirements. Our multi-family documentation establishes standardized installation details, modular components, and efficient distribution approaches that support accelerated construction schedules and cost-effective implementation. These optimized drawings address the unique challenges of residential construction including stacked systems, distribution risers, and repeated unit layouts while ensuring consistent quality and performance across these large-scale developments.

Why Choose Us

Professional MEP Shop Drawing Services That Improve Construction Efficiency

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

MEP shop drawings are detailed fabrication and installation documents that translate design intent into specific construction instructions for mechanical, electrical, and plumbing systems. Unlike design documents that establish general requirements, shop drawings provide exact component dimensions, precise locations, detailed connections, and specific installation information that fabrication teams and field installers need to accurately construct building systems. These documents are critical because they bridge the gap between design concepts and physical implementation, transforming engineering intent into actionable construction information. Shop drawings resolve ambiguities in design documentation, integrate contractor expertise, incorporate manufacturer-specific components, and address field conditions to ensure constructability. They establish exact dimensional control, connection details, and installation sequences that prevent field conflicts and improper installations. Research shows projects with comprehensive shop drawing processes typically experience 30-40% fewer installation issues, 25-35% less rework, and significantly improved schedule performance compared to projects with insufficient fabrication documentation. Beyond addressing technical requirements, shop drawings create contractual alignment between design intent and construction implementation, establishing clear expectations and deliverables for all project stakeholders.

The MEP shop drawing process follows a structured methodology that progressively transforms design intent into detailed fabrication documentation. The process begins with comprehensive design analysis where engineering documents are evaluated for requirements, specifications, and design intent with identification of areas requiring further development or clarification. Based on this analysis, detailed coordination models are developed that integrate architectural constraints, structural elements, and other building systems to establish properly aligned spatial arrangements free from conflicts. These coordinated models then transition to fabrication development where specific manufacturer components, connection details, support systems, and installation requirements are incorporated based on approved submittals and contractor preferences. The shop drawing production phase translates these detailed models into comprehensive documentation including plans, sections, elevations, and details with proper dimensioning, tagging, and annotations that guide fabrication and field installation. These drawings undergo thorough internal review for quality, accuracy, and completeness before submission to design teams for approval. Following review, any required revisions are implemented, and final documents are issued for fabrication and construction implementation. Throughout this process, systematic quality control, coordination verification, and dimensional validation ensures the final documentation accurately represents both design intent and construction requirements while addressing the specific needs of fabrication teams and field installers.

Our MEP shop drawing services address comprehensive building systems and components across all disciplines with appropriate fabrication and installation detail. For mechanical systems, we develop detailed documentation for HVAC equipment installations including air handling units, chillers, boilers, and specialized components with connections, service clearances, and mounting details. Ductwork fabrication drawings include detailed sheet metal layouts, fitting specifications, connection types, reinforcement requirements, and installation instructions with proper dimensioning and sizing information. Mechanical piping documentation covers complete distribution networks with accurate routing, hanger locations, expansion provisions, and connection details for all system types. Electrical shop drawings document distribution equipment, switchgear, panel installations, generator systems, and specialty components with detailed mounting information and connection requirements. Cable tray and raceway layouts include comprehensive routing, support systems, and capacity management with specific fabrication requirements. Lighting system documentation details fixture placement, mounting methods, and connection requirements with appropriate installation instructions. For plumbing and fire protection, our shop drawings include detailed piping layouts, fixture connections, equipment installations, valve arrangements, and specialty components with accurate dimensions and installation parameters. These comprehensive documentation packages address the specific requirements of each building system while providing the detailed fabrication and installation information required for efficient construction implementation.

Our MEP shop drawings deliver substantial construction benefits through comprehensive fabrication planning and detailed installation documentation. The primary efficiency improvement comes through prefabrication enablement, where detailed component documentation allows off-site assembly of system elements including ductwork sections, piping assemblies, electrical racks, and multi-trade modules. This prefabrication approach typically reduces installation labor by 20-30% while improving quality through controlled manufacturing environments. Installation efficiency improves through precise dimensional control, clear assembly instructions, and detailed mounting information that eliminates field interpretation and improves crew productivity. Material optimization occurs through accurate quantification, reduced waste factors, and efficient component utilization that typically decreases material costs by 8-12% compared to field-measured installations. Coordination integration within shop drawings prevents costly conflicts during installation, reducing field rework by 40-60% and minimizing associated schedule delays. For project management, the detailed documentation improves planning accuracy, resource allocation, and schedule development while reducing RFIs and field questions by 50-70%. Throughout construction, these benefits combine to accelerate installation timelines by 15-25%, reduce overall MEP installation costs by 10-15%, and significantly improve system quality compared to projects without comprehensive shop drawing development, delivering substantial economic advantages alongside enhanced project outcomes.

Our MEP shop drawings provide comprehensive detail calibrated to fabrication and installation requirements across all system types. For equipment installations, documentation includes precise dimensional layouts, mounting details, connection points, service clearances, and support requirements with specific anchor locations and load information. Distribution elements feature complete fabrication detail including material specifications, sizing information, connection methods, support locations, and installation parameters. Ductwork documentation specifies sheet metal gauge, reinforcement requirements, transition dimensions, and connection details with proper offsets and fitting specifications. Piping drawings include specific routing dimensions, elevation control, hanger locations, slope requirements, expansion provisions, and connection details for all system types. Electrical documentation details conduit and raceway routes, support methods, pull box locations, and specific installation requirements with appropriate circuit identification. For coordination purposes, shop drawings include elevation control, dimensioning from established datums, and verified clearances to other systems that ensure proper installation alignment. Specialized components receive detailed mounting instructions, connection requirements, and assembly information tailored to specific products and applications. Throughout all documentation, dimensioning follows established standards with appropriate tolerances, reference points, and field verification requirements that support accurate construction implementation. This comprehensive detail transforms generic design information into specific fabrication and installation instructions that substantially improve construction quality and efficiency.

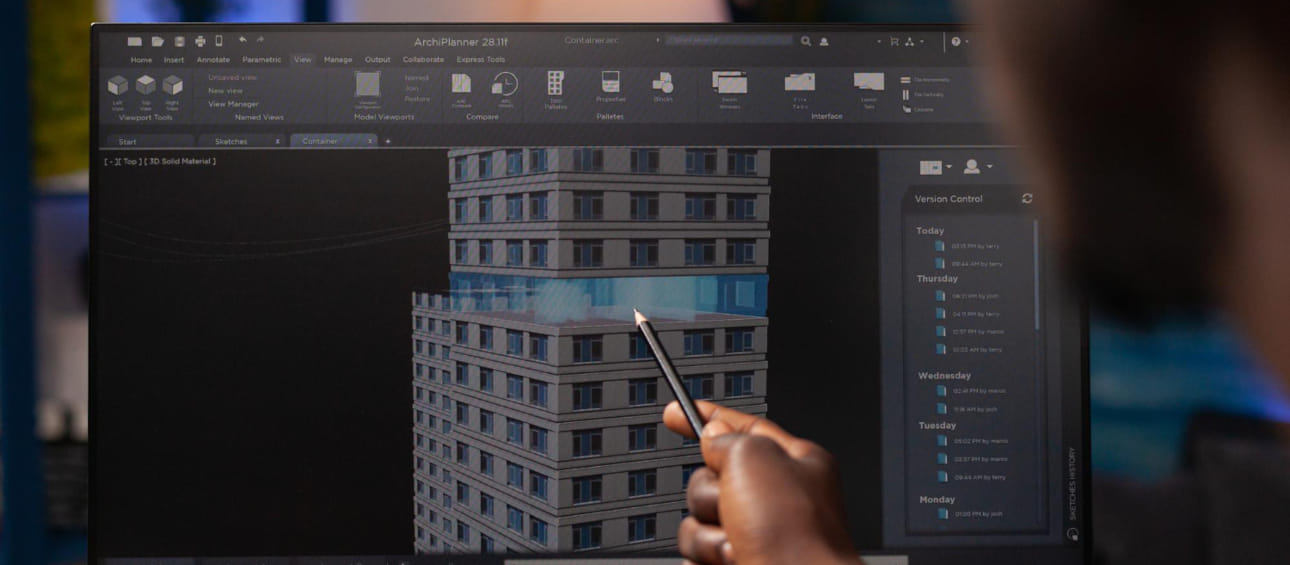

Our MEP shop drawing development utilizes advanced software platforms and technologies optimized for fabrication documentation and construction implementation. The primary modeling environment employs Autodesk Revit MEP with specialized fabrication extensions, detailed component libraries, and manufacturer-specific content that enables precise system representation. For enhanced fabrication documentation, we implement specialized applications including Autodesk Fabrication CADmep, SysQue, and Trimble solutions that provide manufacturing-specific information, connection details, and assembly parameters beyond standard modeling capabilities. These platforms are supplemented by AutoCAD MEP for specialized documentation requirements and detailed component development. For coordination integration, we utilize Navisworks, BIM 360, and specialized review tools that ensure spatial compatibility and conflict-free installations. Production documentation leverages advanced sheet generation systems with automatic dimensioning, tagging protocols, and annotation standards that maintain consistent information presentation across all documents. These technology platforms are continuously updated to incorporate emerging fabrication capabilities, digital manufacturing interfaces, and field implementation tools that enhance construction outcomes. Our technical approach emphasizes interoperability between design platforms, fabrication systems, and field implementation tools to create seamless information flow from engineering concept through physical construction, ensuring optimal documentation regardless of project complexity or specialized system requirements.

Our MEP shop drawings provide essential foundations for prefabrication and modular construction through manufacturing-focused documentation that enables efficient off-site production. For component prefabrication, shop drawings establish precise dimensions, connection details, assembly requirements, and material specifications with manufacturing tolerances that support shop production of system elements including ductwork assemblies, piping racks, and electrical distribution components. Multi-trade coordination within documentation defines module boundaries, interface connections, and assembly relationships that enable integrated prefabrication of ceiling racks, wall assemblies, and service modules with clear understanding of component relationships. For modular construction, drawings establish standardized connection details, transport limitations, rigging requirements, and field interface specifications that support efficient module manufacturing and site integration. Throughout documentation, drawing organization reflects manufacturing sequences, assembly groupings, and installation phases that align with prefabrication workflows and production processes. Specialized notations address manufacturing requirements including welding specifications, assembly sequences, quality control points, and testing provisions necessary for shop production. When digital manufacturing is employed, documentation integrates with fabrication systems through appropriate file formats, parametric definitions, and machine instructions that support automated production. This comprehensive approach transforms traditional shop drawings into complete manufacturing documentation that substantially enhances prefabrication efficiency, improves component quality, and accelerates overall construction delivery through optimized off-site production strategies.

Our MEP shop drawings undergo comprehensive quality control processes that ensure accuracy, completeness, and constructability throughout development and delivery. The quality management system begins with standardized templates, content libraries, and documentation protocols that establish consistent quality foundations across all projects. During development, progressive quality reviews occur at key milestones including coordination completion, component development, and documentation production to identify issues early when corrections are most efficient. Formal quality control implements systematic validation protocols including dimensional verification, specification compliance, coordination confirmation, and standards adherence with dedicated checklists for each system type. These reviews examine technical accuracy (dimensions, sizes, connections), document completeness (required views, details, annotations), coordination integration (spatial alignment, conflict resolution), and fabrication appropriateness (manufacturing feasibility, installation practicality). For complex systems, specialized reviews address engineering parameters, performance requirements, and technical specifications to ensure functional compliance. Final documentation undergoes comprehensive peer review by experienced professionals with specific expertise in fabrication and installation practices for each system type. This multi-layer quality process typically identifies and resolves 95-98% of potential documentation issues before delivery, significantly reducing field problems, revision requirements, and construction delays compared to industry standards. Throughout implementation, quality metrics track performance, identify improvement opportunities, and validate effectiveness to continuously enhance documentation quality across all projects regardless of scale or complexity.

Wide Range of SERVICES

Other MEP BIM Services

Browse our specialized mechanical, electrical, and plumbing design services that ensure optimal building system performance, efficiency, and integration.

Create detailed BIM models for mechanical, electrical, and plumbing systems, ensuring proper integration with architectural and structural elements.

Coordinate mechanical, electrical, and plumbing systems to resolve conflicts and optimize space utilization within building environments.

Create precise technical drawings for mechanical, electrical, and plumbing systems, including plans, sections, and details for construction.

Model site and building utilities including water, sewer, stormwater, and energy systems for improved coordination and construction planning.