BIM Quantity Takeoff Services

In modern construction planning and cost management, BIM-based quantity takeoffs have revolutionized how material quantities are measured, extracted, and utilized throughout project development. Our specialized quantity takeoff services extract precise measurements directly from detailed building information models, providing accurate material quantities, component counts, and dimensional calculations that support cost estimation, procurement planning, and construction management. This data-driven approach delivers unprecedented accuracy, comprehensive coverage, and significantly improved efficiency compared to traditional measurement methods.

Measurement & Estimation

- Precise material quantities extracted directly from building information models

- Comprehensive measurement of architectural, structural, and MEP components

- Detailed reports with proper classification, coding, and specification references

- Enhanced accuracy compared to traditional takeoff methods with reduced errors

- Direct support for cost estimation, procurement, and construction planning

Comprehensive Quantity Extraction Methodology

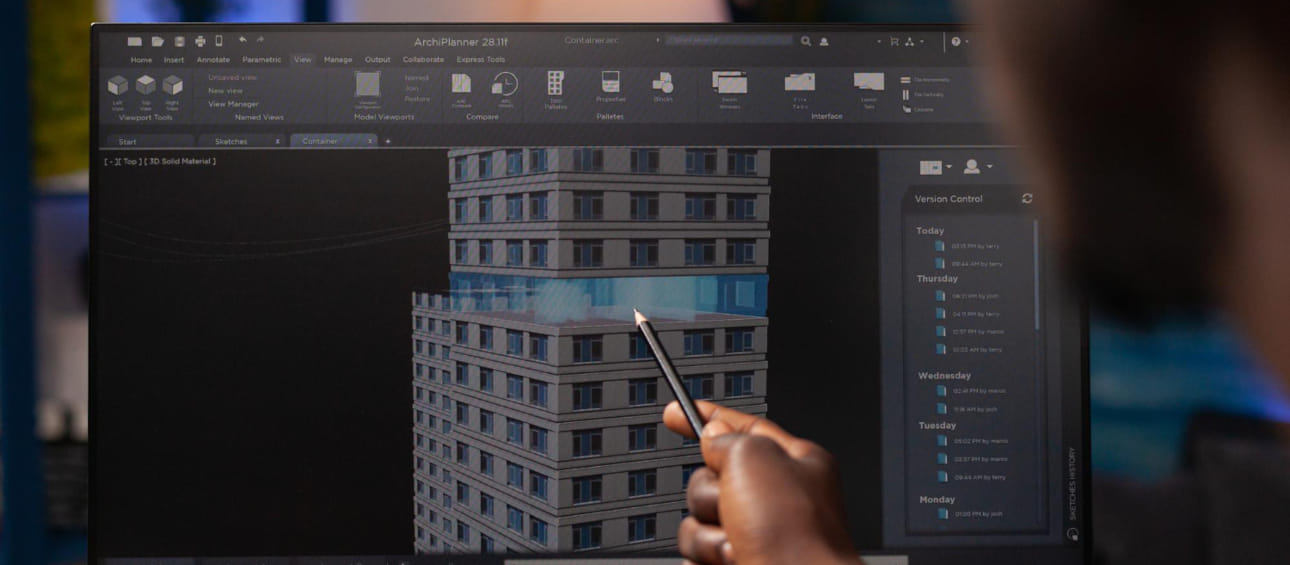

Our BIM-based quantity takeoff services implement a structured extraction approach that systematically measures materials and components with maximum accuracy and reliability. We begin with detailed model assessment to evaluate information quality, component structure, and parameter organization that informs appropriate extraction strategies. From this foundation, we develop tailored measurement processes with custom schedules, calculation formulas, and specialized views that optimize data organization and ensure comprehensive coverage of all building elements.

The systematic extraction process addresses different construction systems in logical sequence, applying appropriate measurement methods including volumetric calculation, area extraction, linear measurement, or component counting based on industry standards and project requirements. Throughout extraction, our rigorous validation protocols verify quantity accuracy, confirm measurement boundaries, and ensure calculation correctness through visual confirmation, mathematical cross-checking, and systematic sampling. The extracted quantities are organized into structured reports with appropriate categorization, cost coding, specification references, and location breakdown that support effective estimation and procurement applications. This comprehensive approach transforms building model data into precise, reliable material measurements that significantly enhance both cost estimation and construction planning across diverse project applications.

Strategic Benefits of BIM-Based Quantity Takeoffs

Implementing BIM-based quantity takeoffs delivers substantial advantages throughout project planning, cost management, and construction implementation. The primary benefit comes through unprecedented accuracy, where quantities derive directly from the 3D geometry and component properties rather than scaled dimensions or drawing interpretation that frequently introduce errors in traditional takeoffs. This approach typically improves quantity accuracy by 15-25% compared to manual methods, substantially enhancing estimate reliability and reducing contingency requirements.

Efficiency improvements transform the traditionally time-intensive takeoff process through automated extraction, systematic calculation, and digital organization that collectively reduce measurement time by 40-60% while significantly improving both scope coverage and calculation reliability. For complex or irregular shapes, the precise geometric calculation of curved surfaces, compound volumes, and non-standard forms significantly improves measurement accuracy compared to simplified approximations frequently used in conventional takeoffs. Throughout construction planning, these capabilities support enhanced scope verification, detailed material procurement, optimized resource management, and effective change tracking that collectively improve project delivery outcomes. By providing precise, comprehensive material measurements with improved reliability and organizational clarity, BIM-based quantity takeoffs substantially enhance cost certainty, improve resource planning, and transform traditional quantity surveying into data-driven project intelligence throughout the complete construction lifecycle.

Applications of BIM Quantity Takeoffs

Construction Cost Estimation

Comprehensive quantity takeoffs for general contractors, construction managers, and estimating teams with detailed measurement requirements and cost planning objectives. Our estimation takeoffs address material quantities, component counts, assembly measurements, and dimensional calculations with appropriate cost coding systems and specification references. These detailed measurements support accurate unit pricing, reliable total cost development, and improved estimation confidence throughout project bidding and financial planning processes.

Material Procurement Planning

Specialized quantity extraction for purchasing teams, material suppliers, and procurement specialists with detailed requirements for ordering, fabrication, and delivery scheduling. Our procurement takeoffs address specific material quantities, dimensional requirements, phasing breakdowns, and location-based information supporting efficient purchasing workflows. These comprehensive measurements enhance material ordering accuracy, reduce waste factors, improve delivery coordination, and optimize inventory management throughout construction implementation.

Construction Planning & Scheduling

Detailed quantity measurement for construction teams, project managers, and planning specialists with specific requirements for resource allocation and schedule development. Our planning takeoffs provide comprehensive quantities with appropriate location breakdowns, phase distribution, and work categorization supporting detailed construction planning. These organized measurements support crew allocation, equipment planning, production rate calculation, and timeline development throughout project execution planning and schedule optimization.

Value Engineering & Change Management

Specialized comparative takeoffs for design teams, project managers, and owner representatives with requirements for alternative analysis and modification assessment. Our analytical takeoffs provide detailed quantity comparisons between design options, version changes, and scope modifications with clear identification of differences and impacts. These comparative measurements support informed decision-making, accurate change pricing, and effective scope management throughout design development and construction implementation.

Why Choose Us

Advanced Quantity Takeoff Services That Enhance Cost Estimation and Material Planning

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

BIM-based Quantity Takeoffs are the systematic extraction of precise material quantities, component counts, and dimensional measurements directly from Building Information Models instead of traditional paper drawings or 2D documentation. Unlike conventional manual takeoff methods that rely on scale measurements and visual interpretation, BIM-based takeoffs extract data directly from the intelligent 3D model where each component contains specific dimensional properties, material definitions, and classification parameters. This approach has become increasingly critical for construction projects because it provides unprecedented accuracy, comprehensive coverage, and significantly improved efficiency in quantity extraction. The data-driven nature of BIM takeoffs enables consistent methodology, eliminates interpretation variations, and maintains direct connections to design information that collectively enhance estimating reliability. Industry studies show that projects implementing comprehensive BIM-based quantity takeoffs typically experience 40-60% reduced takeoff time, 15-25% improved quantity accuracy, and significant enhancements in both cost estimation reliability and material management effectiveness. Beyond these quantifiable benefits, BIM takeoffs provide enhanced scope visualization, improved project understanding, better estimation transparency, and more effective change management capabilities that collectively transform traditional quantity surveying into data-driven project intelligence throughout the complete construction lifecycle.

Our BIM-based quantity takeoff process follows a structured methodology that systematically extracts comprehensive material quantities and component measurements with maximum accuracy and reliability. We begin with model assessment, evaluating BIM quality, component structure, parameter organization, and information completeness to establish appropriate extraction strategies and validation requirements. Initial planning defines quantity organization, measurement standards, classification systems, and reporting formats based on project requirements and estimation methodology. For extraction preparation, we develop custom parameters, shared schedules, calculation formulas, and specialized views that optimize data organization and measurement accuracy. The systematic extraction process addresses different construction systems in logical sequence, beginning with structural elements and building envelope before progressing through interior components, finishing elements, and specialized systems. For each material category, we implement appropriate measurement methods including volumetric calculation, area extraction, linear measurement, or component counting based on industry standards and project requirements. Quantity validation implements comprehensive verification protocols including visual confirmation, mathematical cross-checking, parameter validation, and systematic sampling that ensure measurement accuracy and completeness. For complex or unusual components, specialized extraction methods address unique geometries, composite assemblies, and non-standard elements with tailored approaches that maintain measurement consistency. Data organization formats extracted quantities into structured reports with appropriate categorization, cost coding, specification references, and location breakdown that support effective estimation and procurement applications. The completed takeoffs undergo comprehensive quality review examining mathematical accuracy, extraction methodology, classification consistency, and reporting clarity to ensure reliable quantities for construction applications. This systematic approach ensures all building elements receive appropriate measurement regardless of complexity while maintaining consistent methodology and reliable results throughout the complete quantity takeoff process.

Our BIM-based quantity takeoff services address comprehensive material categories and component types across all building systems with appropriate measurement methodologies and extraction approaches. For structural systems, we extract concrete volumes, reinforcement tonnage, structural steel weights, connection components, and formwork areas with proper classification and type separation. Building envelope quantities include wall areas, insulation volumes, cladding systems, roofing materials, and waterproofing elements with accurate measurements of both gross and net areas accounting for openings and penetrations. Interior finish takeoffs address flooring areas, ceiling types, wall finishes, paint surfaces, and covering materials with appropriate breakdown by room, level, and finish type. Architectural elements include doors, windows, fixtures, specialties, and furnishings with accurate component counts, size breakdowns, and type classifications. Mechanical system quantities encompass equipment units, ductwork areas, piping lengths, insulation volumes, terminal devices, and distribution components with proper sizing categories and system separation. Electrical takeoffs extract conduit lengths, cable tray measurements, fixture counts, device quantities, and distribution equipment with appropriate circuit categorization and system organization. Plumbing and fire protection quantities include pipe lengths, fitting counts, fixture units, equipment items, and distribution components with proper material separation and system classification. Site and civil measurements extract earthwork volumes, pavement areas, landscaping elements, site fixtures, and infrastructure components with appropriate quantity organization. Each material category receives tailored extraction approaches based on industry standards, measurement conventions, and estimation requirements, creating comprehensive quantity packages that support both cost estimation and procurement planning regardless of project type or construction methodology.

BIM-based quantity takeoffs deliver substantial estimating advantages and cost benefits through data-driven extraction and comprehensive measurement capabilities. The primary accuracy benefit comes through direct model measurement, where quantities derive directly from the 3D geometry and component properties rather than scaled dimensions or drawing interpretation that frequently introduce errors in traditional takeoffs. This approach typically improves quantity accuracy by 15-25% compared to manual methods, substantially enhancing estimate reliability and reducing contingency requirements. Extraction completeness benefits from comprehensive model visualization that clearly identifies all components, reveals hidden elements, and prevents the omissions or duplications common in traditional takeoff methods. For complex or irregular shapes, the precise geometric calculation of curved surfaces, compound volumes, and non-standard forms significantly improves measurement accuracy compared to simplified approximations frequently used in conventional takeoffs. These accuracy improvements typically reduce quantity-related contingencies by 30-50%, decrease material overages by 10-15%, and significantly enhance bid confidence and competitiveness. Beyond direct measurement benefits, BIM takeoffs enable enhanced scope verification, improved constructability analysis, and detailed design review that collectively identify and address potential cost issues during preconstruction rather than during physical implementation. Throughout project delivery, these capabilities support procurement optimization, value engineering, change management, and progress tracking that collectively enhance cost control and budget management. By providing precise, comprehensive material measurements with improved reliability and transparency, BIM-based quantity takeoffs substantially reduce cost uncertainty, improve resource allocation, and enhance overall project financial outcomes throughout the complete construction process.

Our BIM-based quantity takeoff services provide comprehensive deliverables tailored to project requirements and estimation needs across diverse construction applications. The primary deliverable includes detailed quantity reports with organized measurement data, material breakdowns, component counts, and dimensional calculations formatted in clearly structured spreadsheets with appropriate classification, coding systems, and specification references. These reports include proper quantity units, measurement standards, and calculation methodologies that establish clear understanding of extraction approaches and measurement conventions. For location-based management, quantities include appropriate breakdown by building level, project phase, construction zone, or functional area that supports detailed planning and sequencing strategies. Visual documentation includes annotated model views, highlighted extraction areas, and 3D representations that demonstrate measurement boundaries, clarify scope inclusions, and identify specific components for improved understanding. Calculation documentation provides transparent formulas, measurement methods, and quantification approaches that establish clear audit trails and verification processes for all extracted quantities. For integration with cost estimating, our deliverables include properly formatted exports compatible with common estimating platforms including Sage, Procore, HCSS, or specialized systems that streamline data transfer and utilization. When change management is required, comparison reports identify quantity differences between model versions, highlight affected components, and quantify specific modifications that support effective variation management. All deliverables maintain consistent organization, clear identification, and accessible structure that support effective utilization throughout construction planning, procurement, and implementation processes. This comprehensive approach provides complete quantity information that enhances both cost estimation and construction management regardless of project scale or complexity, delivering precise measurement data that substantially improves decision-making throughout the complete construction lifecycle.

Our BIM-based quantity takeoffs implement comprehensive quality assurance protocols that ensure extraction accuracy, calculation reliability, and measurement completeness throughout the takeoff process. The foundation for quality begins with model verification, systematically examining BIM completeness, component accuracy, parameter consistency, and geometric integrity to identify potential extraction issues before beginning the takeoff process. For extraction methodology, standardized procedures establish consistent approaches, measurement conventions, and calculation formulas that maintain uniform quantification regardless of model complexity or component variation. Systematic validation employs multi-method verification including visual confirmation where quantities are compared against model visualization to confirm appropriate component selection and boundary definition. Mathematical cross-checking applies alternative calculation methods to verify results, comparing different extraction approaches to identify potential discrepancies or measurement anomalies. For material classification, rigorous verification confirms proper categorization, type assignment, and specification alignment to ensure quantities organize correctly within reporting structures and estimation systems. Sampling validation implements statistical examination across representative model areas, performing detailed verification of sample sections to confirm extraction accuracy across the complete model. For complex geometries, specialized verification protocols address unique shapes, composite assemblies, and atypical components with tailored approaches that ensure measurement reliability. Comprehensive reporting reviews examine organizational clarity, calculation transparency, unit consistency, and information completeness to ensure deliverables effectively support estimation processes. Final deliverables undergo independent peer review by experienced quantity surveyors with expertise in both BIM extraction and construction methodology. This multi-layer quality process typically resolves 95-98% of potential measurement issues before delivery, significantly improving quantity reliability, estimation accuracy, and project cost certainty compared to conventional takeoff methods. Throughout all quality processes, transparency and auditability remain primary objectives, ensuring BIM takeoffs provide verifiable quantities with clear extraction methodology and traceable calculation approaches.

Our BIM-based quantity takeoffs provide powerful support for cost estimation and bidding processes through comprehensive material measurement, enhanced scope visualization, and detailed component analysis that substantially improve financial planning and tender preparation. For initial budgeting, early-stage quantities enable conceptual estimating with appropriate level of detail and classification structure, providing reliable measurement data even during schematic design when project definition remains incomplete. These early quantities typically improve budget accuracy by 15-25% compared to area-based estimates, substantially enhancing financial planning and funding decisions. During design development, progressive quantity extraction enables continuous cost feedback, providing updated measurements as models evolve that support value engineering, design optimization, and budget management throughout project development. For detailed estimation, comprehensive takeoffs provide precise measurement for unit price application, material costing, labor calculation, and subcontractor scope definition with appropriate breakdown and organization that streamline pricing processes. This thorough quantification typically reduces estimation time by 30-40% while significantly improving cost reliability and pricing confidence. Bid preparation benefits from enhanced scope understanding, clear quantity definition, and comprehensive measurement that collectively improve subcontractor solicitation, vendor quotation, and internal pricing with clear scope communication and transparent quantity information. Throughout tender processes, these capabilities support detailed scope review, alternative analysis, value engineering, and clarification responses that enhance both competitive positioning and risk management. By providing precise, comprehensive material measurements with improved reliability and organizational clarity, BIM-based quantity takeoffs substantially enhance estimation quality, improve pricing accuracy, and increase bid confidence throughout the complete preconstruction process, delivering significant competitive advantages across diverse project types and delivery methods.

Our BIM-based quantity takeoffs provide substantial support for material procurement and construction planning through detailed component quantification, enhanced spatial understanding, and comprehensive measurement data that significantly improve implementation strategies and resource management. For procurement planning, precise material quantities enable accurate purchasing requirements, appropriate order sizing, and reliable delivery scheduling that collectively optimize material acquisition and reduce both shortages and excess inventory. This precision typically improves material utilization by 8-12%, reduces emergency purchases by 40-60%, and substantially enhances both cost efficiency and schedule reliability throughout construction implementation. Vendor solicitation benefits from detailed quantity breakdowns, clear material specifications, and comprehensive scope definition that improve quotation accuracy, reduce pricing uncertainty, and enhance subcontractor understanding during procurement processes. For construction planning, location-based quantities support detailed scheduling, crew allocation, equipment requirements, and resource loading with appropriate breakdown by area, level, or project zone that enhance implementation strategy and sequence development. Material management benefits from precise delivery requirements, storage planning, and distribution strategies based on accurate quantity information and installation timing that substantially improve site logistics and handling efficiency. Throughout construction, comprehensive quantities support progress tracking, earned value analysis, payment verification, and performance monitoring with reliable measurement benchmarks for completed work assessment. When design changes occur, model-based quantity comparison identifies specific modifications, affected components, and scope adjustments that improve change management, variation pricing, and impact assessment throughout project implementation. By providing detailed quantity information with appropriate organization, classification, and location reference, BIM-based takeoffs transform traditional material management into data-driven resource optimization that substantially improves construction efficiency, reduces waste, and enhances implementation outcomes throughout the complete construction process.

Wide Range of SERVICES

Other Specialized Services

Discover our advanced specialized BIM services addressing unique project requirements and specific industry applications with tailored solutions.

Create digital twins of buildings and facilities that combine BIM data with real-time information for improved operations and maintenance.

Develop custom Revit families for building components, furniture, equipment, and specialized elements to support detailed BIM modeling.

Develop Construction Operations Building Information Exchange (COBie) data sets from BIM models to support facility management and operations.