Reverse Engineering Services

In today's built environment, Reverse Engineering provides crucial documentation and analysis for buildings, components, and systems where original records are unavailable or unreliable. Our specialized services combine advanced measurement technologies with engineering expertise to create accurate digital representations of existing assets—recreating not just geometric forms but also system functionality, material properties, and design logic. We deliver comprehensive digital models that explain how buildings and systems actually work, creating valuable documentation for facilities where original information has been lost to time, inadequate record-keeping, or ownership transitions.

- Digital recreation of existing buildings and systems without original documentation

- Engineering analysis to determine system functionality and component properties

- Comprehensive modeling of architectural, structural, and building systems

- Non-destructive investigation of concealed elements and assemblies

- Creation of intelligent BIM assets from legacy buildings and installations

Comprehensive Reverse Engineering Solutions

Our Reverse Engineering services deliver complete digital recreation of existing buildings and systems through systematic analysis and modeling of current physical conditions. Unlike standard documentation that might focus only on visible elements, our reverse engineering approach involves comprehensive investigation to understand not just geometric forms but also the underlying engineering logic, construction methods, material properties, and system behaviors that define how assets actually function. This deeper analysis creates intelligent digital representations that explain existing buildings and systems completely, even when original documentation is entirely absent.

We provide reverse engineering solutions for diverse building assets—from complete facilities and complex systems to individual components and specialized installations that require detailed digital recreation. Our capabilities address buildings of any age or complexity, with particular value for legacy assets where documentation has been lost over time or never properly maintained. Whether analyzing historic structures with traditional construction methods, mid-century buildings with evolving technologies, or specialized facilities with unique systems, our reverse engineering methodology creates accurate digital representations that capture both physical form and functional intelligence, providing the critical information needed for ongoing management and future modifications.

Strategic Benefits of Reverse Engineering

Reverse Engineering delivers transformative benefits for buildings and systems where documentation gaps create significant operational and modification challenges. For facility owners and managers, these services create the missing system knowledge essential for effective operations, informed maintenance, and proper modification planning—replacing undocumented tribal knowledge with reliable digital information that persists beyond staff transitions. This improved information foundation eliminates the perpetual rediscovery of building systems that occurs when documentation is inadequate, creating substantial operational efficiencies while reducing risks associated with uninformed interventions in complex systems.

For renovation and modification projects involving undocumented facilities, reverse engineering creates the reliable baseline information essential for effective design development and successful implementation. The comprehensive understanding developed through reverse engineering reveals constraints, identifies opportunities, and enables precise integration of new elements with existing conditions. This improved certainty significantly reduces design inefficiencies, prevents costly field discoveries, and minimizes change orders resulting from documentation gaps. Throughout the project lifecycle, reverse engineered information supports better decision-making, more accurate cost planning, and more efficient construction implementation—transforming high-risk projects involving undocumented assets into manageable endeavors with predictable outcomes.

Industry Applications of Reverse Engineering

Legacy Facility Renovation

Specialized reverse engineering for older buildings, aging infrastructure, and historic structures requiring comprehensive renovation with limited original documentation. Our legacy facility services recreate accurate digital representations of buildings from any era, capturing both visible elements and underlying systems. These detailed models support renovation design, system upgrades, and modern integrations while maintaining understanding of original construction logic and critical preservation elements.

Industrial & Specialized Systems

Comprehensive reverse engineering for industrial facilities, specialized equipment, and custom installations lacking proper documentation. Our industrial system services analyze complex mechanical, electrical, and process systems to determine configurations, capacities, and operational parameters. These detailed digital recreations support system maintenance, component replacement, capacity expansions, and operational optimization for specialized facilities where original documentation is incomplete or outdated.

Digital Twin Development

Advanced reverse engineering to create comprehensive digital twins of existing facilities for advanced management and operational applications. Our digital twin services develop intelligent models that integrate geometric documentation with system functionality, performance parameters, and operational data. These sophisticated digital representations support advanced facility management, predictive maintenance, performance optimization, and virtual simulation for existing buildings where original documentation lacks the detail needed for modern digital applications.

Property Portfolio Documentation

Strategic reverse engineering for real estate portfolios, institutional campuses, and facility networks requiring standardized documentation of diverse buildings. Our portfolio services create consistent digital representations across multiple facilities regardless of age, original documentation quality, or historical record availability. These standardized models establish reliable portfolio-wide information that supports strategic planning, capital allocation, and operational standardization across diverse property holdings.

Why Choose Us

Advanced Reverse Engineering That Creates Knowledge from Undocumented Assets

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

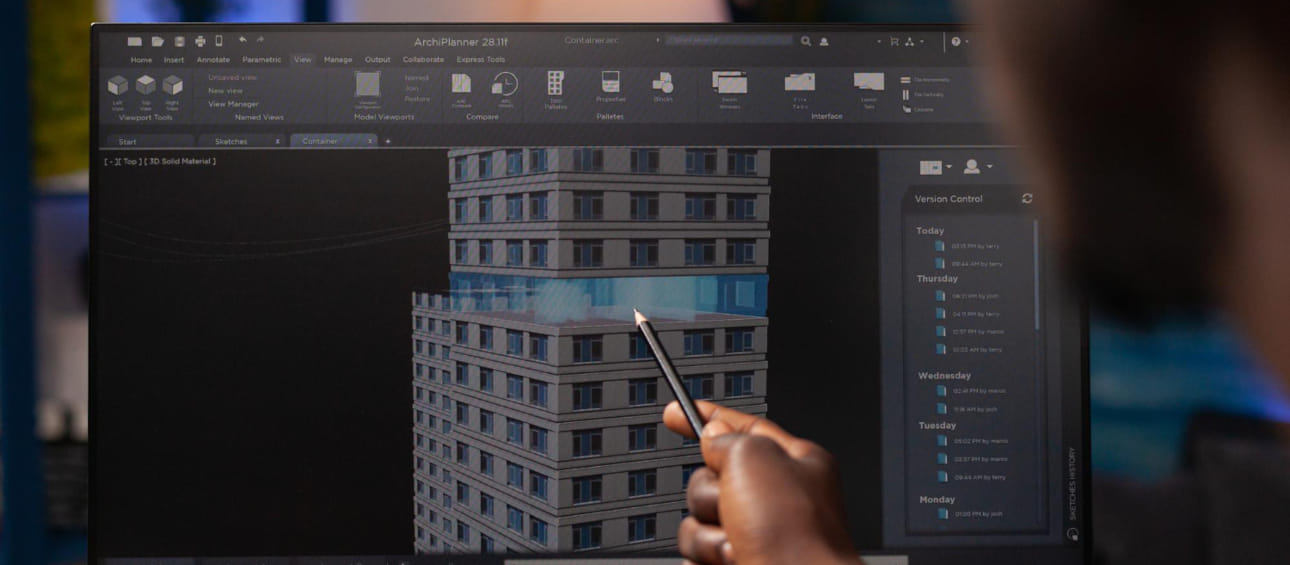

BIM Reverse Engineering is the specialized process of creating accurate Building Information Models of existing buildings, components, or systems where original documentation is unavailable, outdated, or unreliable. Unlike standard documentation that might focus only on visible elements or basic dimensions, reverse engineering involves comprehensive analysis to understand not just the geometry but also the functional logic, construction methods, material properties, and system performance characteristics of existing assets. This process combines advanced measurement technologies like laser scanning with engineering expertise to deduce how systems were designed, determine component properties, infer structural logic, and recreate complete digital representations that include both visible elements and underlying systems. The resulting models provide not just geometric documentation but intelligent information that explains how buildings and systems actually function—creating complete digital twins of existing assets that support modification design, performance analysis, and ongoing management.

Our BIM Reverse Engineering services can address virtually any existing building asset regardless of age, complexity, or available documentation. For complete buildings, we reverse engineer entire structures including architectural configurations, structural systems, and building services with appropriate component intelligence and system relationships. Individual system reverse engineering addresses specific building aspects such as structural frames, mechanical systems, electrical distribution, specialized equipment, or custom components requiring detailed digital recreation. We also provide targeted reverse engineering for unique architectural elements including historic features, complex geometries, ornamental components, and custom assemblies that require precise digital documentation. Beyond conventional buildings, our capabilities extend to specialized facilities including industrial complexes, infrastructure components, heritage structures, and unique installations where original documentation is unavailable. This comprehensive capability ensures effective reverse engineering solutions regardless of building type, age, or complexity—creating accurate digital representations that support ongoing management, modification design, or replacement planning.

Our Reverse Engineering approach integrates multiple technologies and methodologies to achieve comprehensive digital recreation of existing assets. Advanced measurement technologies form the foundation, including high-precision laser scanning that captures millions of dimensional points, photogrammetry for detailed surface documentation, and specialized tools like ground-penetrating radar or thermography for non-visible elements. These capture methods are supplemented by traditional investigation techniques including selective component examination, material testing, performance monitoring, and operational analysis that reveal functional characteristics. For complex systems, we employ engineering analysis to deduce design intent, loading patterns, capacity parameters, and performance specifications that explain how systems function. Throughout the process, our BIM specialists integrate these diverse information sources through intelligent modeling platforms including Revit, specialized engineering software, and computational analysis tools that transform raw data into coherent digital representations. This multi-faceted approach enables complete reverse engineering that captures not just physical form but also functional intelligence, material properties, and system behaviors within comprehensive Building Information Models.

Addressing incomplete information and inaccessible areas requires specialized approaches that balance factual documentation with engineering analysis and informed assumptions. For partially visible systems, we implement engineering inference techniques that deduce complete configurations from observable portions based on logical extension, standard practices, and system requirements. When dealing with concealed elements like structural components, internal systems, or foundation elements, we utilize non-destructive investigation technologies including ground-penetrating radar, thermal imaging, and ultrasonic testing that reveal information without destructive access. For elements that remain unobservable, we apply analytical modeling using engineering principles, performance characteristics, and building era practices to develop probable configurations based on observable behaviors. Throughout this process, our documentation maintains strict differentiation between directly measured elements, inferred components, and engineered assumptions through parameter tagging, confidence ratings, and verification notes that clearly communicate information reliability. This transparent approach ensures reverse engineered models provide maximum utility while maintaining clear understanding of information sources and confidence levels for all building elements.

Our Reverse Engineering services can achieve multiple detail levels calibrated to project requirements, available information, and intended applications. For geometric documentation (LOD 200-300), we capture accurate dimensions, spatial relationships, and basic material differentiation of all observable components with appropriate simplification of complex elements. When system functionality is critical (LOD 300-350), we extend modeling to include mechanical operation, electrical organization, and structural logic with parametric intelligence that explains how systems work. For detailed component reverse engineering (LOD 350-400), we model precise assemblies, connection methods, and material specifications that support manufacturing or replacement planning. The highest detail level (LOD 400-500) creates comprehensive digital twins with complete component definition, material properties, performance parameters, and maintenance information for facility management applications. The appropriate detail level is established during project planning based on critical requirements—higher precision for manufacturing integration, system modifications, or performance simulation; standard definition for spatial planning or general documentation. This calibrated approach ensures reverse engineered models provide exactly the information needed without excessive detail when not required.

Our BIM Reverse Engineering follows a structured methodology refined through extensive project experience. The process begins with comprehensive requirements analysis to determine critical information needs, detail level specifications, and model applications that shape the approach. Initial investigation combines building examination, available documentation review, and stakeholder consultation to establish baseline understanding before technical measurement begins. For data acquisition, we implement appropriate capture technologies including laser scanning, photographic documentation, and specialized investigation methods based on project requirements. Analysis and interpretation follows with engineering evaluation of captured data to determine construction methods, system configurations, and functional logic that explain how elements work together. The modeling phase implements a systematic approach that begins with primary structural and spatial elements before developing detailed components and systems with appropriate parametric intelligence. Throughout development, continuous quality assurance protocols verify dimensional accuracy, component functionality, and information content according to established standards. The final delivery phase includes model optimization, documentation completion, and comprehensive deliverable preparation including appropriate metadata, confidence information, and usage guidance. This systematic approach ensures consistent quality, appropriate detail, and complete deliverables regardless of project complexity.

Reverse Engineered BIM models provide powerful support for both modification design and ongoing management through comprehensive digital representation of existing assets. For renovation and modification projects, these models create accurate spatial and system baselines that reveal constraints, identify opportunities, and enable precise integration of new elements with existing conditions. The intelligent nature of reverse engineered components supports conflict detection, performance analysis, and construction planning that reduces risk in modification projects. When system replacements are required, the detailed component understanding supports precise specification, integration planning, and installation logistics that ensure successful implementation. For facility management applications, reverse engineered models provide the system documentation typically missing for older buildings, enabling informed maintenance planning, component replacement, and performance optimization. The digital twin aspect of comprehensive reverse engineering creates virtual representations that support ongoing simulation, monitoring, and predictive analysis as facilities evolve. These diverse applications extend the value of reverse engineering investments far beyond initial documentation, creating digital assets that support the entire remaining building lifecycle regardless of original documentation limitations.

Our Reverse Engineering services provide comprehensive deliverables tailored to project requirements and intended applications. Standard deliverables include native BIM models (typically Revit) with appropriate component intelligence, parametric behavior, and information classification structured for downstream applications. These models are supplemented by industry-standard exchange formats including IFC, NWD, and specialized engineering formats that support diverse workflows. Documentation deliverables derived from reverse engineered models include floor plans, elevations, sections, and component details with proper dimensional information and annotation standards. For engineering applications, we provide analytical documentation including capacity assessments, performance parameters, and system specifications derived from reverse engineering analysis. All deliverables include appropriate metadata including modeling standards, confidence ratings, information sources, and assumption documentation that establishes clear reliability expectations. For complex projects, we supplement standard deliverables with point cloud references, investigation reports, and engineering analyses that explain derivation methodologies and support model validation. This comprehensive deliverable approach ensures reverse engineered information provides maximum value across diverse applications from modification design through facility management.

Wide Range of SERVICES

Other Scanning Services

Explore our advanced scanning and reality capture services that create accurate digital representations of existing buildings and sites for renovation and documentation.

Capture detailed point cloud data of existing buildings and sites using LiDAR technology, providing accurate dimensional documentation.

Transform 3D point cloud scan data into accurate BIM models of existing buildings, capturing as-built conditions with precision and detail.

Document existing buildings and facilities through comprehensive as-built drawings and models based on field measurements or scan data.