Shop Drawings Extraction Services

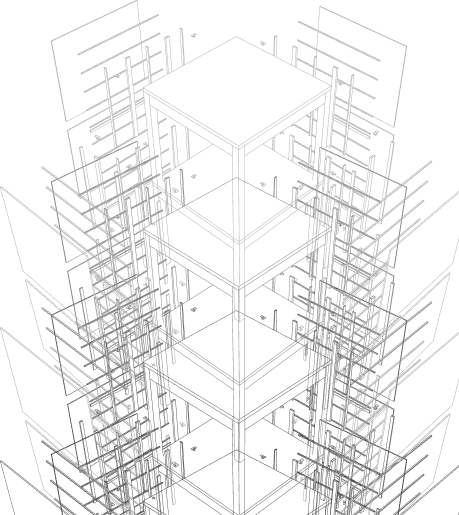

In today's precision-driven construction industry, BIM-based Shop Drawing Extraction services provide essential documentation for component fabrication and installation. Our specialized extraction services develop detailed manufacturing-ready documentation directly from coordinated building information models, ensuring dimensional accuracy, material precision, and system compatibility. We create comprehensive shop drawings for diverse building components and systems including structural elements, architectural features, mechanical assemblies, and specialty items—all with the detail and specificity required for successful fabrication and efficient field installation.

Shop Drawing Services

- Comprehensive fabrication documentation derived directly from coordinated BIM models

- Detailed component drawings with precise dimensions and material specifications

- Complete connection and assembly details for manufacturing and installation

- System-specific shop drawings for structural, architectural, and MEP components

- Prefabrication support documentation for modular and off-site construction

Comprehensive Shop Drawing Solutions

Our Shop Drawing Extraction services provide manufacturing-ready documentation that bridges the gap between design intent and fabrication requirements. We leverage the intelligence within building information models to create detailed component documentation that includes precise dimensions, material specifications, connection details, and assembly instructions required for accurate manufacturing. Unlike traditional shop drawings that are manually created from design documents, our BIM-based approach maintains direct connections to the coordinated model, ensuring dimensional accuracy, system compatibility, and construction feasibility while streamlining the documentation process.

We develop shop drawings tailored to specific building components and manufacturing processes, with appropriate detail levels and annotation standards for each application. Our services address the unique requirements of various building systems from structural steel fabrication and precast concrete production to curtain wall manufacturing and mechanical system fabrication. Each shop drawing package includes comprehensive component information, piece identification systems, material schedules, and assembly details organized according to industry standards and fabricator preferences. This system-specific approach ensures that shop drawings provide exactly the information needed for successful manufacturing while maintaining coordination with the overall building model.

Strategic Benefits of BIM-Based Shop Drawings

BIM-based Shop Drawings deliver significant advantages for construction projects by improving fabrication accuracy and installation efficiency. The direct connection to coordinated building models ensures that manufactured components will properly fit their intended locations without field modifications or rework. This integration reduces construction errors, minimizes field adjustments, and accelerates installation timelines by resolving fabrication issues virtually before manufacturing begins. Studies indicate that comprehensive shop drawing development can reduce field installation time by 15-25% while minimizing material waste and improving quality control throughout the fabrication process.

Beyond accuracy improvements, BIM-based shop drawings enable advanced construction strategies including increased prefabrication, modular assembly, and just-in-time delivery. The detailed component information supports off-site manufacturing processes where controlled environments improve quality and efficiency. For complex projects, comprehensive shop drawings enhance procurement planning, material tracking, and installation sequencing while providing clear communication between design teams, fabricators, and field installers. Throughout construction, these detailed documents support quality verification, progress tracking, and as-built documentation that improves both immediate project delivery and long-term facility management.

Industry Applications of Shop Drawings

Structural Steel Fabrication

Comprehensive shop drawings for structural steel elements including beams, columns, connections, and specialty assemblies. Our structural steel documentation provides complete manufacturing information with material specifications, weld details, bolt requirements, and assembly sequences. These specialized drawings include piece marks, CNC data, and erection information that supports automated fabrication, quality control, and efficient field installation of complex structural systems.

Curtain Wall & Facade Systems

Detailed shop drawings for building envelope components including curtain wall systems, window assemblies, panel systems, and architectural features. Our facade documentation addresses the specialized requirements of these systems including extrusion details, gasket specifications, glass types, thermal breaks, and anchorage methods. These precision drawings support manufacturing processes, assembly planning, and installation sequencing for these critical aesthetic and performance elements.

MEP System Fabrication

Specialized shop drawings for mechanical, electrical, and plumbing system components including ductwork, piping, equipment connections, and distribution networks. Our MEP fabrication documentation addresses the unique requirements of these systems including sizing, routing, fitting specifications, insulation requirements, and support systems. These trade-specific drawings enable off-site prefabrication, multi-trade coordination, and efficient installation of complex building systems.

Modular & Prefabricated Construction

Comprehensive documentation for modular building components, prefabricated assemblies, and integrated systems designed for off-site manufacturing. Our prefabrication documentation addresses the specialized requirements of these approaches including module definitions, connection interfaces, transportation considerations, and assembly sequencing. These integrated drawings support advanced construction strategies that improve quality, accelerate schedules, and enhance installation efficiency for complex building projects.

Why Choose Us

Precision Shop Drawing Documentation That Enables Successful Fabrication

01

Expert Team

Certified BIM specialists with extensive experience across architectural, MEP, and facade modeling projects

02

Comprehensive Services

End-to-end BIM solutions from initial modeling to coordination, documentation, and facility management

03

Quality Assurance

Rigorous quality control processes ensuring clash-free models, accurate documentation, and seamless collaboration

04

Dedicated Support

Responsive team available to assist throughout your project lifecycle, ensuring timely solutions and continuous assistance

Know More

Frequently Asked Questions

BIM-based Shop Drawings are detailed fabrication and installation documents derived directly from coordinated building information models rather than being drafted independently. Unlike traditional shop drawings that are created manually from design intent documents, BIM-based Shop Drawings maintain parametric intelligence, dimensional accuracy, and spatial coordination from the original model. This direct extraction ensures consistency between fabrication documentation and the coordinated building model, reducing errors and improving precision. BIM-based Shop Drawings include complete material specifications, connection details, and assembly information with the added benefit of maintaining relationships with other building systems to ensure proper fit and integration during installation.

Our Shop Drawing Extraction services can document a comprehensive range of building components and systems. For structural elements, we produce detailed steel fabrication drawings, precast concrete shop tickets, reinforcement details, and connection assemblies. In architectural applications, we develop curtain wall and facade component drawings, millwork and casework details, specialty feature documentation, and custom element specifications. For building systems, we generate mechanical ductwork and piping fabrication drawings, electrical distribution layouts, plumbing system details, and fire protection documentation. Additionally, we provide specialized documentation for modular construction components, prefabricated assemblies, equipment integration, and custom building elements requiring detailed manufacturing information.

BIM-based Shop Drawings provide comprehensive fabrication-level detail appropriate for manufacturing and installation purposes. Typical documentation includes precise dimensional information with tolerances appropriate to the building system and manufacturing process. Material specifications detail exact product requirements including grades, finishes, treatments, and performance characteristics. Connection and joinery information defines assembly methods with appropriate fastener specifications, welding details, or integration requirements. The drawings include proper component identification, piece marks, and tagging systems that support fabrication tracking, quality control, and field installation. For complex elements, we provide assembly sequence information, installation guidelines, and relationship documentation that coordinates multiple trades or prefabricated elements.

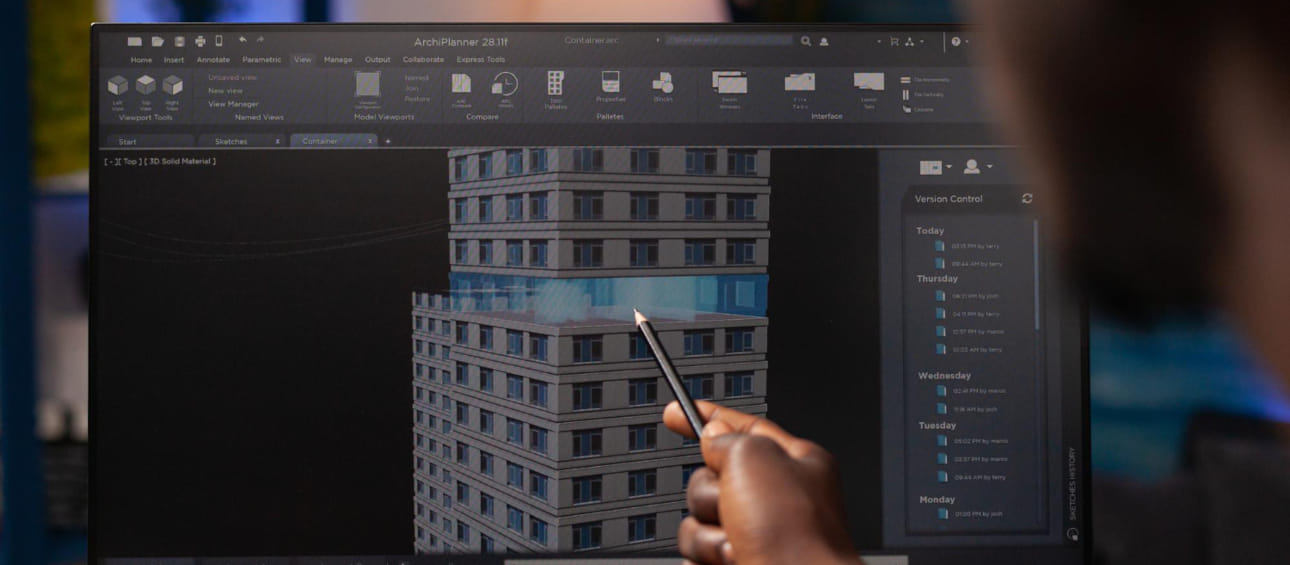

We employ specialized software platforms tailored to specific building systems and fabrication requirements. For structural steel, we utilize Tekla Structures, Advance Steel, and SDS/2 for comprehensive fabrication documentation. Our architectural component extraction leverages Revit with specialized add-ins like AGACAD Wood Framing and CASE apps for detailed fabrication views. MEP shop drawings are developed using Revit MEP, Fabrication CADmep, and SysQue for trade-specific detailing. We employ specialized tools including Inventor and SolidWorks for complex component detailing where appropriate. Our extraction workflows include standardized view templates, annotation systems, drawing standards, and data exchange protocols that ensure consistent quality across all shop drawing deliverables while accommodating specific fabricator requirements and manufacturing methods.

We maintain comprehensive coordination between shop drawings and other building systems through our integrated BIM-based approach. All shop drawing extraction occurs after multi-discipline clash detection and coordination processes have verified spatial compatibility between systems. The extraction process preserves the geometric relationships established during coordination, ensuring that fabricated components will properly integrate with other building elements. For critical interfaces, we provide detailed interface control drawings that document the relationship between adjoining systems with appropriate tolerances and connection specifications. Throughout the shop drawing development, we implement regular cross-checking procedures that verify continued alignment with the coordinated model as shop-level details are refined. This approach ensures that fabrication documents remain fully coordinated even as they progress to manufacturing-level detail.

Our BIM-based Shop Drawing development follows a structured methodology that ensures manufacturing-ready documentation. The process begins with a thorough review of design intent, performance requirements, and coordination status to establish appropriate detailing parameters. We then implement progressive model development focusing on specific building components at fabrication-level detail including proper material attributes, connection details, and manufacturing information. As the fabrication model matures, we configure specialized extraction views with appropriate scale, dimensioning, notation, and detail references optimized for manufacturing clarity. These views are organized into systematic sheet sets with standard titleblocks, revision controls, and approval workflows. Throughout development, regular quality control reviews verify dimensional accuracy, material specifications, and fabrication feasibility before final production. The completed shop drawings undergo appropriate approval processes before release for manufacturing.

BIM-based Shop Drawings provide the precise documentation foundation essential for successful prefabrication and modular construction strategies. The direct connection to coordinated building models ensures that prefabricated elements will integrate properly with other building components without field modifications. Our shop drawings provide complete manufacturing information including assembly sequences, connection details, and shipping considerations that support off-site fabrication processes. For modular construction, our documentation defines module boundaries, interface connections, and tolerance management strategies that enable successful field assembly. The parametric intelligence within BIM-based shop drawings supports rapid adjustment when design changes occur, maintaining coordination throughout the prefabrication process. Additionally, our documentation includes transportation planning, lifting considerations, and installation sequencing that address the specialized logistics requirements of prefabricated construction.

Our Shop Drawing Extraction services provide comprehensive documentation tailored to specific manufacturing and installation requirements. Standard deliverables include complete drawing sets with appropriate title sheets, general notes, material schedules, and fabrication details organized according to industry conventions. These packages include both overview drawings showing component relationships and detailed manufacturing information at appropriate scales. We provide drawings in multiple formats including native CAD files (typically DWG), PDF sets at production-ready resolution, and specialized formats for manufacturing equipment where required. For digital fabrication, we can deliver CNC-ready files, material optimization reports, and fabrication data exports compatible with automated manufacturing systems. All deliverables undergo comprehensive quality review with detailed checking documentation to verify completeness, accuracy, and manufacturing feasibility before release.

Wide Range of SERVICES

Other BIM Coordination

Discover our comprehensive coordination services that ensure seamless integration between all building systems, minimizing conflicts and optimizing construction efficiency.

Coordinate multi-discipline models to identify and resolve conflicts before construction, improving project efficiency and reducing costly site rework.

Identify and resolve spatial conflicts between building systems using advanced BIM clash detection tools and methodologies.

Leverage BIM to support prefabrication strategies, enabling off-site manufacturing of building components for faster, more efficient construction.